INDUSTRIAL, OFFLINE

TERMINAL RAILROADS &

RAIL-MARINE OPERATIONS

OF BROOKLYN, QUEENS, STATEN

ISLAND, BRONX &

MANHATTAN:

Development of the Carfloat

Transfer Bridge in New York Harbor Jersey pontoon float railroad rail marine

ferryapron French Bensel Mallery NYNJ Rail Pennsylvania Haven

Hartford Baltimore Ohio Central Long Island Oak Point Brooklyn Queens

Bronx Staten Island

Manhattan Harsimus Greenville Weehawken Hoboken Claremont Hell Gate Bay

Ridge NYNH&H LIRR PRR NYC West Shore Hudson River

East

. .

.

www.transferbridgesofnyc.info

| updated: TUESDAY, 07 May 2024 - 15:45 |

||

|

|

||

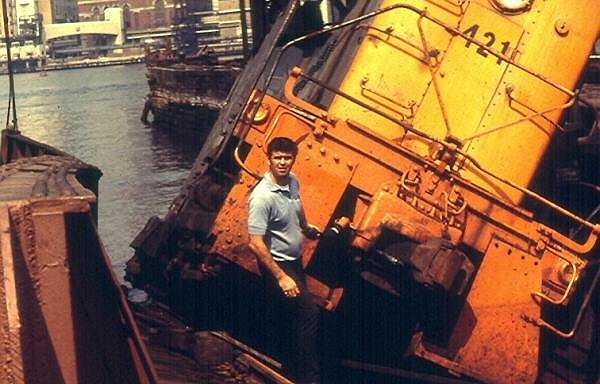

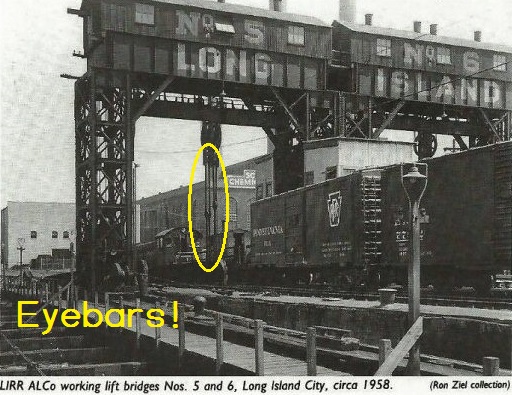

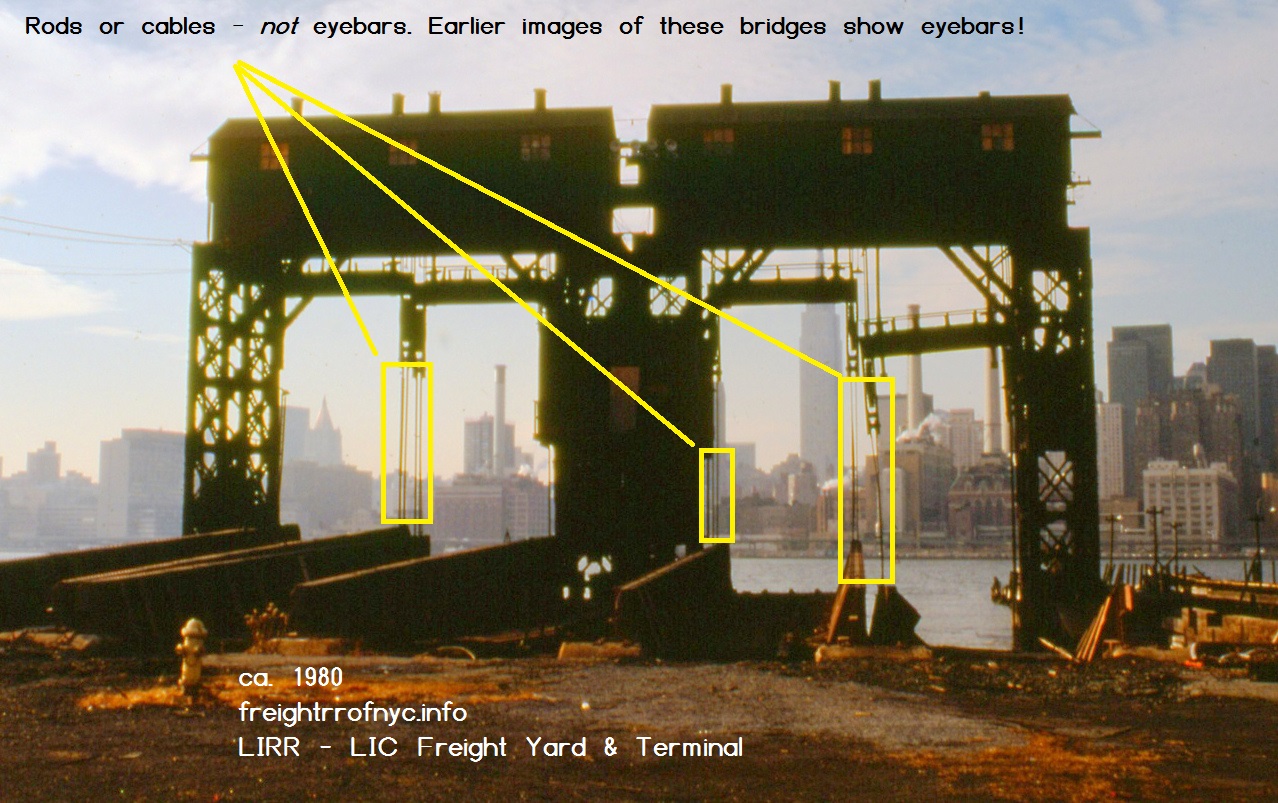

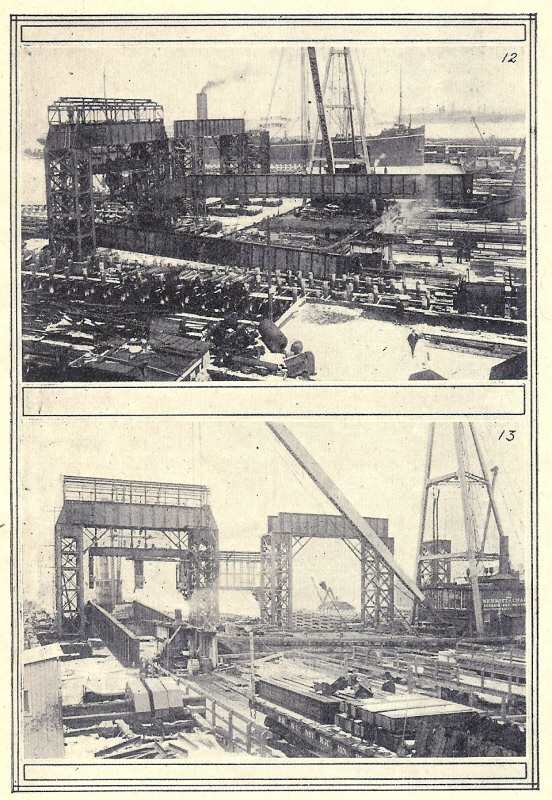

| the 1970 LIRR Bridge 5 collapse | 07 May 2024 | LIRR LIC Transfer Bridge 5 Collapse of 1970 |

| photo of a LIRR steam locomotive on a transfer bridge | 06 May 2024 | A Popular Misconception |

..

.

.

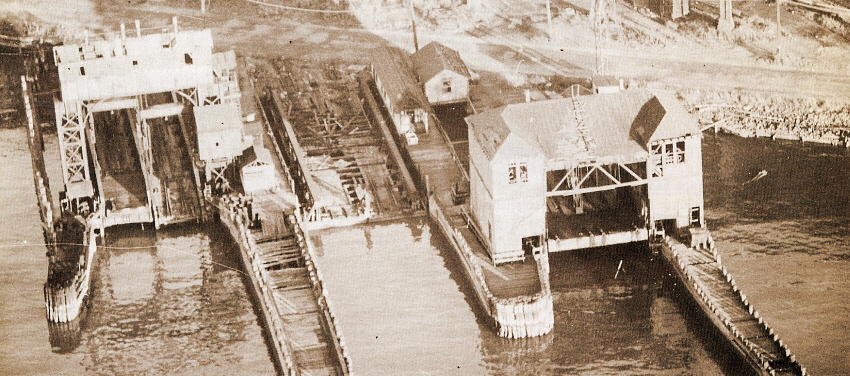

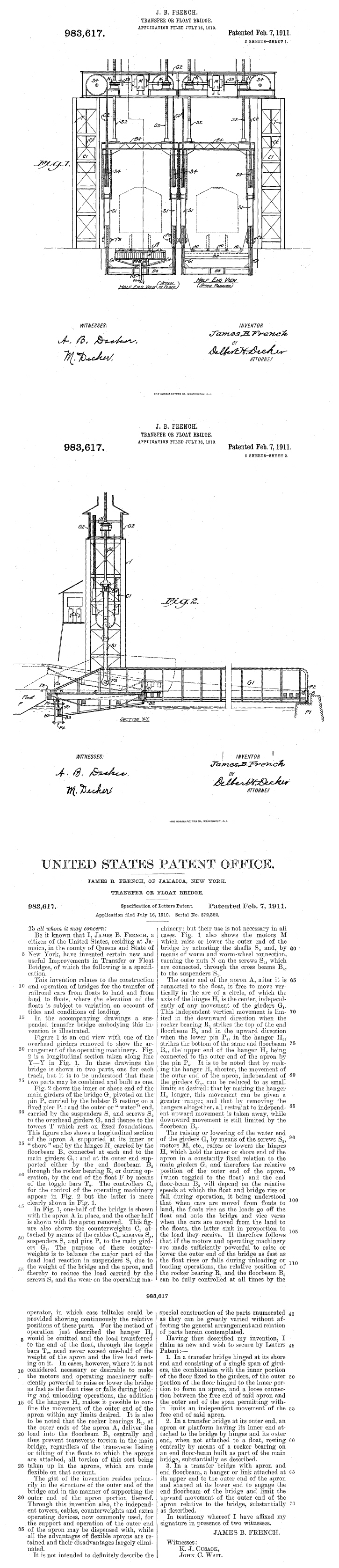

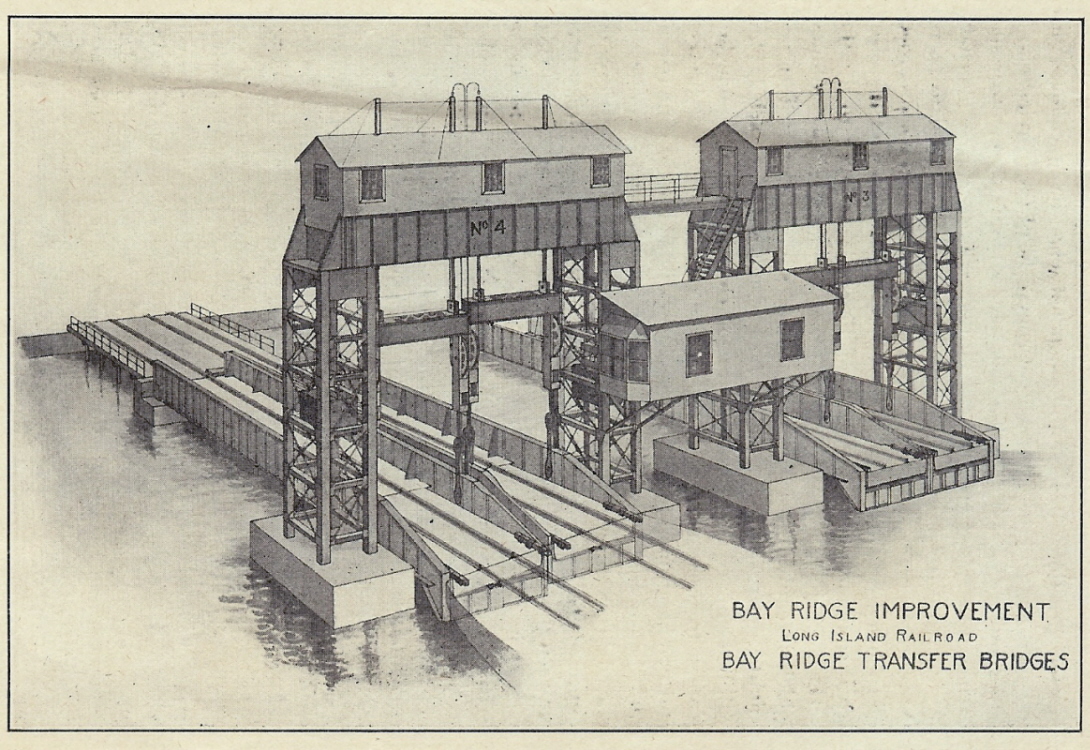

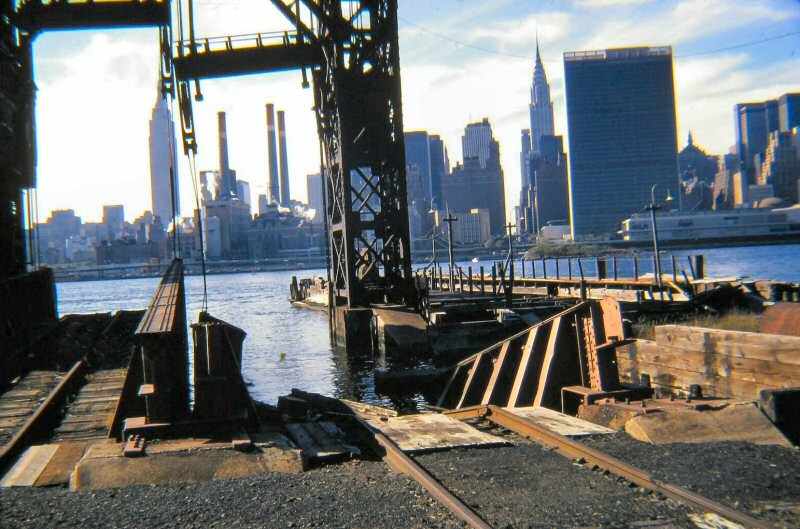

Three types of transfer bridges in one location: New

York Central Railroad West 60th Street Terminal, Manhattan, NY - 1978

| left: electrically

operated Overhead Suspension Contained Apron "J. B. French patent" center: Pontoon / Steel Pony Truss right: electrically operated Overhead Suspension Separate Apron "J. A. Bensel patent" |

T. Flagg

photo

added 04 January 2012

.

.

|

Readers please note:

Furthermore, the terms used on this page were

those used in New York Harbor float / transfer bridge operations, |

.

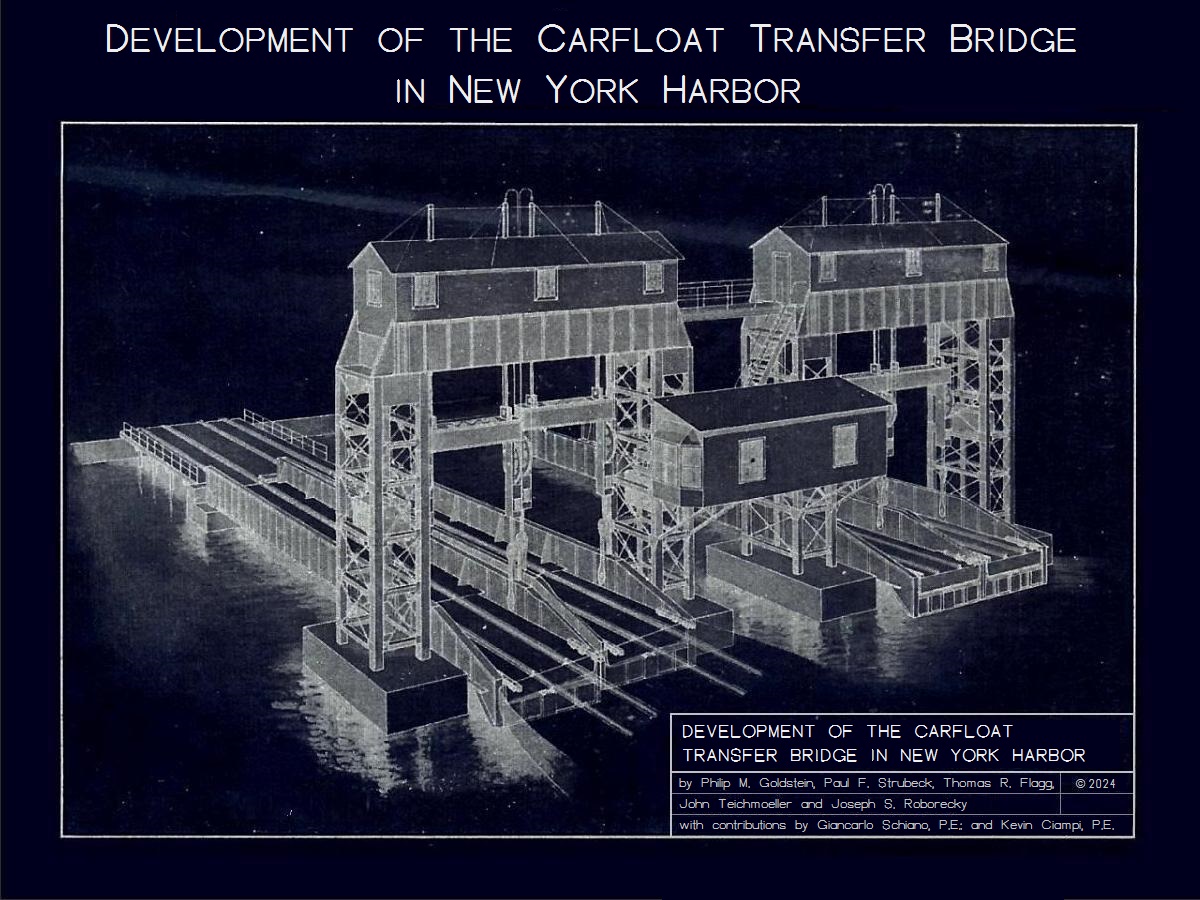

If the title of this page sounds familiar, that is because James B. French's benchmark book of 1917 bears the same title. Sometimes, you just can't come up with a better title than that used before! However, where as French's book primarily covered the development of his contained apron design, this page will encompass all the various designs of float bridges as that information is encountered.

The information on this page was originally located on the main page of this website. It was brief and concise for the intent of giving the novice reader a basic understanding of the methods and technology used for rail-marine operations.

As with anything on this website, what started out with the most basic of information turned into a work of great magnitude, as should be with all good things of interest. Further reinforcing the expansion of this information, was that it was determined that more than just the novice reader was known to have referenced this information. So little by little, more and more diagrams, illustrations and detailed information were added. On top of which, I had purchased an original of J. B. French's 1917 book on the Development of the Carfloat Transfer Bridge in New York Harbor some time ago, so I had scanned it and included it on the main page to share with the rest of those interested parties.

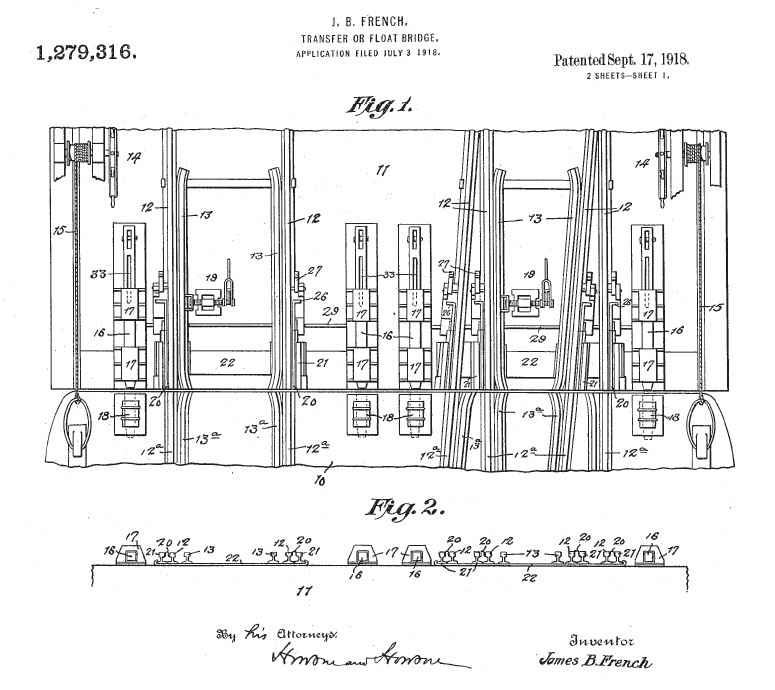

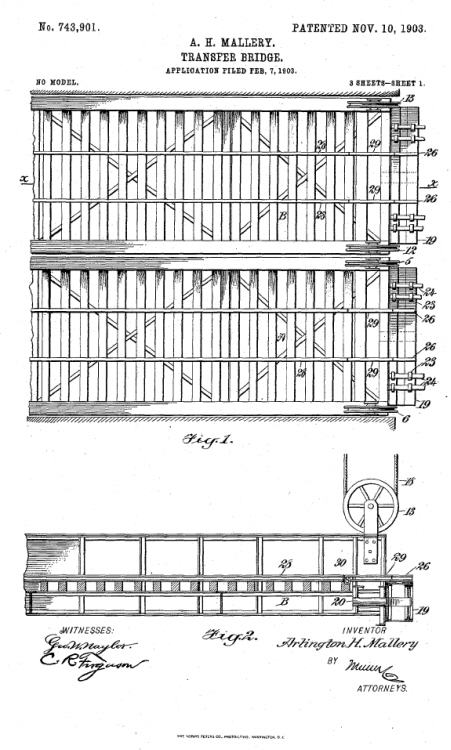

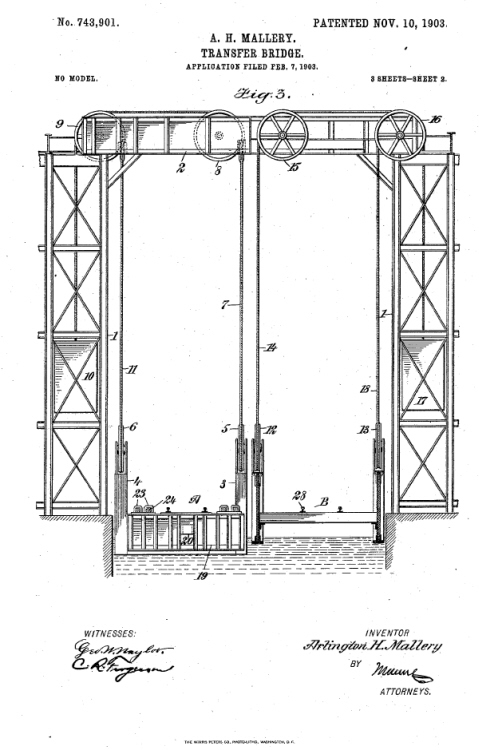

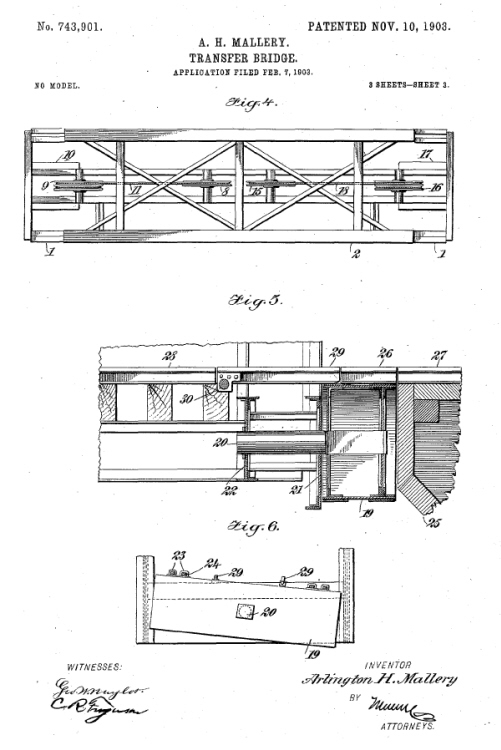

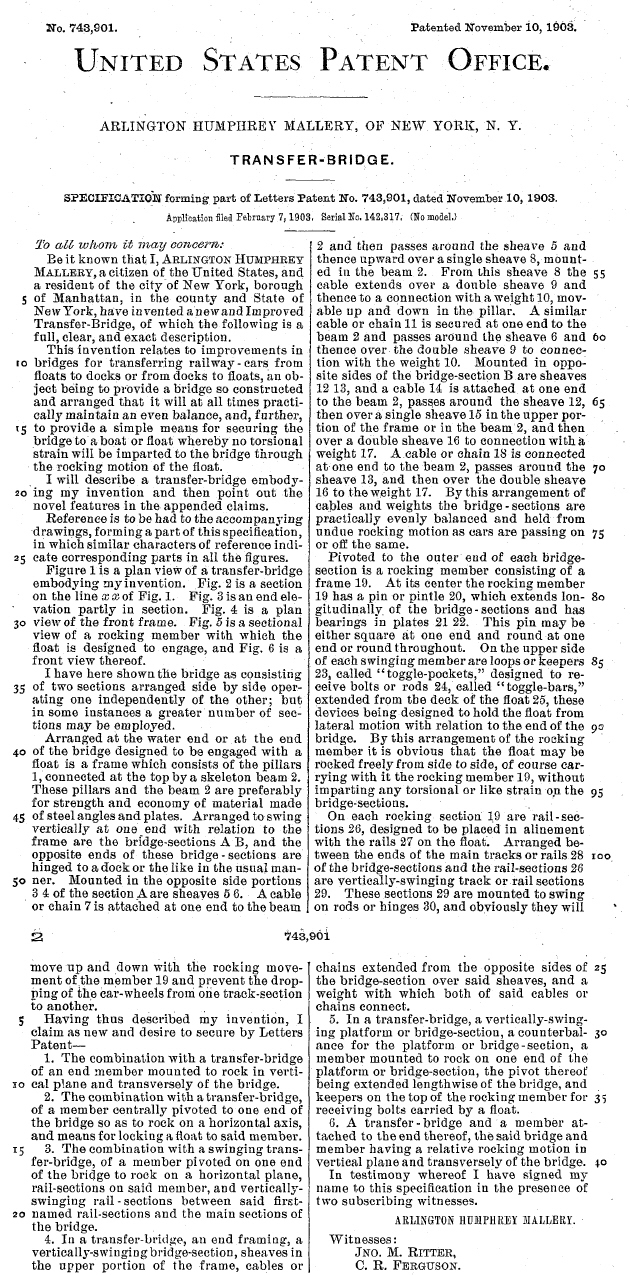

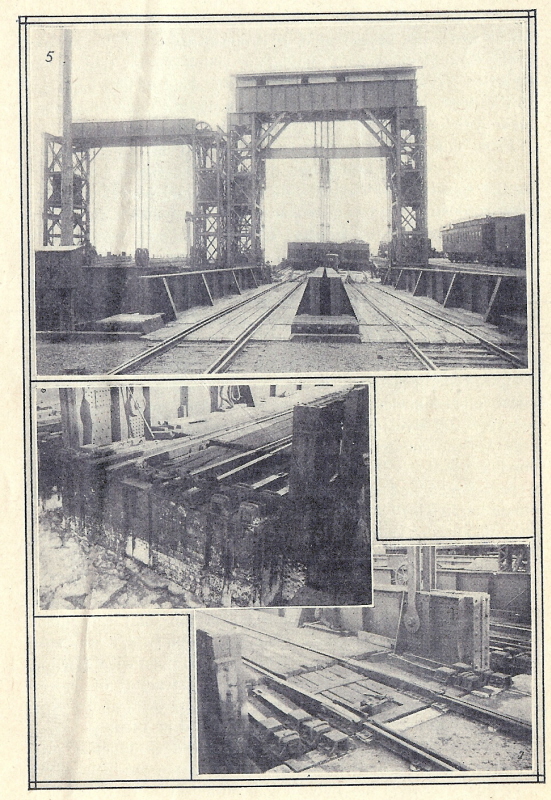

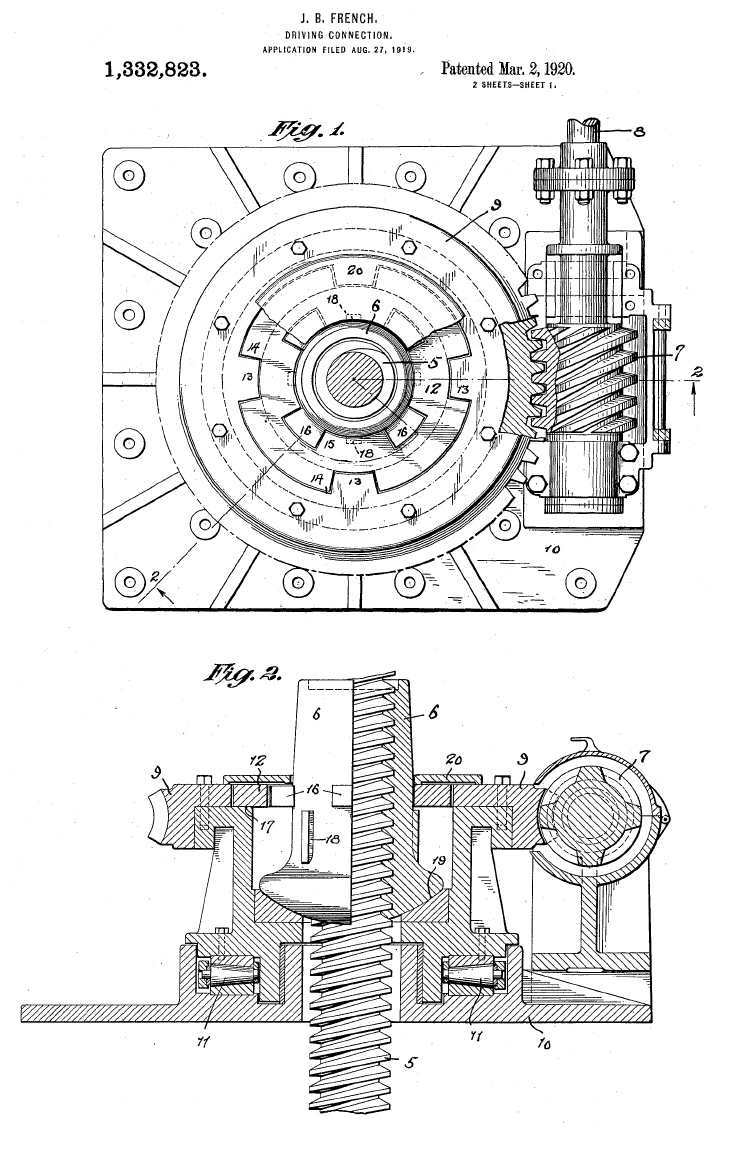

Following requests by readers for better & larger scans, I re-scanned the book. Then on 31 December 2011, Paul Strubeck located illustrations and the patent filing of the Mallery "Swiveling Head Block" type transfer bridge bridge as well as illustrations and patent filing for J. B. French's "Contained Apron" type, both of which in turn was the inspiration for creating this dedicated page to transfer bridge histories.

As a result, the section of transfer bridges grew longer, and took even more time to open. So, it became obvious this information would need to be relocated to its own page. Then came the next obvious decision: to solicit Tom Flagg to join us for the expansion. Tom's interest in industrial archeology has led him to amass an extensive amount of plans, images, and documents on the subject of transfer bridges. And, as he had already published some of this information on transfer bridges, most notably his feature length articles which were published in four parts in Issues 12, 13, 15 & 23 of the Rail Marine Information Group's periodical publication "Transfer"; it was only logical to ask him to join us.

Tom granted his whole hearted and enthusiastic approval and

so, it became our goal to combine on this page in one easy reference:

All of Tom's feature length articles, his general information in his New York Harbor Railroads books, both of these subsequently updated on this page with known information since the original publication dates of those articles;

With those of the older published articles such as the: 1888 Bensel / American Society of Civil Engineers Discussion, 1901 Railway Age, 1903 Mallery Patent filing, 1905 Railway Age, 1911 French Patent filings, French's 1917 book on the Development of the Carfloat Transfer Bridge, among many others;

As well as any other contemporary informational sources as we acquire them, published or discovered after Tom's original publishing in "Transfer".

The four recognized parts of Tom's series: "Overview & Pontoon", "Separate Apron", "Swiveling Head Block and Contained Apron", and the "Recap", have been reorganized. The corrections and further explanations as noted in the recap (Part IV) have been integrated into their respective areas, and the "Swiveling Head Block" and "Contained Apron" chapters were split from one published article into two separate chapters.

Furthermore, not having to deal with the space restrictions of a one or two page spread in a standard bound and printed book or periodical, we are able to use much larger images and illustrations here.

I wish to make it clear, that despite our re-publication and reformatting of Tom's articles as they originally appeared in those four issues of Transfer, it is highly recommended that you still purchase the back issues (digital) of the appropriate Transfer issues (if not the entire series), as there are other articles in those issues that are more than worth reading in their own right.

Back issues of the "Transfer" as published by the Rail Marine

Information Group may be purchased from:

.

|

.

Speaking of John, we must extend our deepest gratitude to him for granting permission for re-publishing and adding further personal research.

Now, that having been stated, it was our intention to replace and / or integrate the basic information originally published here as authored by Philip M. Goldstein and Paul F. Strubeck, with that of Thomas R. Flagg's in depth work. There are two reasons for this:

Our original (PMG, PFS) work was basic in its nature (with the exception of a few items), and was sort of a "primer" as you will, but almost all of the information came from either already existing published works (ironically, these were the same works that TRF used only a decade or so prior), or basic knowledge passed on to us, through the assistance of Paul Strubeck.

In retrospect, Tom's existing work is quite

honestly so much better in regards to citing references, in-person

observations and interviews that he conducted with personnel directly involved

with rail - marine operations,

however;

As Tom's articles in the transfer were published more than a decade ago, quite a bit of history has transpired in the New York Harbor area since then. So an update to his information was only logical.

So when you happen to notice that Tom's work was not reproduced verbatim, you will know why..

Add this to the cooperation and contributions of two professional engineers: Giancarlo Schiano and Kevin Ciampi; both of who are directly involved in the design and construction of modern transfer bridges.

Also bearing mentioning and gratitude are our other two regular contributors to this page:

Joseph S. Roborecky, retired locomotive engineer; who now proofreads the websites, assists in web searching, as well as troubleshoots our I.T. issues; and

John McCluskey, who having resides within spitting distance of the NYNJ Brooklyn operations, keeps us up to date with or obtains images upon request.

.

.

Why the interest

in the Development of Carfloats & Float

Bridges?

. To better understand the success of carfloating to and from the Offline Terminal railroads, we need to discuss the unique method of getting the freight cars to those terminals. It is too easy to think in simplistic terms that the railcar was merely placed by the railroad in front of the business, to be loaded or unloaded.

Carfloating was a necessity where a railroad could not lay direct connecting trackage to the specific destination, whether due to

Several locations throughout the United States and Canada other than New York Harbor witnessed the successful use of rail-marine operations, to include (but not limited to and perhaps inadvertently omitting some):

| "West Coast" | . | San Francisco, CA |

| "Pacific Northwest" | Seattle, WA; Whittier, AK; Squamish, BC, Vancouver, BC; as well as numerous private timber / lumber lines in that region | |

| "Mid Atlantic" | Philadelphia, PA; Baltimore, MD; Wilmington, DE; Norfolk, VA | |

| "Great Lakes" | Chicago, IL; Detroit, MI; Milwaukee, WI | |

| "Gulf" |

Mobile, AL; New Orleans, LA |

.

With the exception of referencing the first recorded use of transfer bridges during the Civil War as a starting point; it is New York Harbor Rail-Marine Operations that will be referenced to in the development of the carfloat transfer bridge for the remaining purposes and content of this website.

.

Carfloating cut down on this transportation distance and travel time significantly, especially in terms for expedited, perishable cargoes such as: fruits, vegetables and livestock.

Even by todays modern rail standards, the expedient way to ship a freight car to Brooklyn from the mainland of the United States (west of the Hudson River), remains to be by carfloat.

And it must also be kept in mind that; with the exception of the Pennsylvania Railroad / New York New Haven & Hartford Railroad's Bay Ridge Branch / New York Connecting Railroad that provided through service from New Jersey to the Bronx and New England; all other remaining eastbound carfloating operations in New York Harbor concluded at freight terminals. In other words, freight cars were removed at a terminal for loading / unloading for final disposition and not transported or interchanged for further transport east.

..

.

.

History of Early

Carfloating

(Or how to get freight cars from here to there by

water.)

.

So in order to load and unload the railcars themselves from the carfloats, the carfloats would be moored to the device known as the float bridge and that's where the pontoon type float bridge came in. But, the actual design of the local float bridge had to be figured out at that point.

This dilemma had been solved by the invention and development of the carfloating and the "float bridge" or "transfer bridge". The history of the the first railroad car transfer bridge in the United States, reflects that it was built in 1838 under a joint venture by the Camden & Amboy and Baltimore & Potomac Railroads to provide passenger car ferry service across the Susquehanna River at Harve De Grace and Perryville, Maryland.

.

Understanding the Differences between "Carferrying"

and "Carfloating"

It should be understood that the primary difference between carferrying and carfloating is thus:

Car ferrying essentially is a way to take entire trains (freight or passenger) across bodies of water; at a location where for various reasons a bridge or tunnel would have been impractical. Once this train has been ferried from one shore to the other, it would continue on its journey to its final destination, which may be hundreds of more miles from the ferrying point. Of course, when a bridge could be built over (or a tunnel under) that waterway at a later date, it would be; thereby greatly reducing those delays in those trains having to use car ferry transportation.

Carfloating on the other hand, at least in regard to New York Area operations, started primarily as an extension to a terminal operation dedicated specifically for freight, which is quite different from car ferrying. Of course, carfloating was used where a bridge was impractical as well. This became especially so, as freight traffic grew and destinations all around the harbor were added to the terminal. Many bridges would be needed to span the Hudson, East & Harlem Rivers and since the bridges and their associated approaches would need to be built tall enough as not to impede the marine traffic, a great deal of very valuable real estate would be wasted on the shores of New York Harbor and connecting estuaries! Carfloats however, could deliver anywhere along the hundreds of miles of waterfront in the region, over tax-free "real estate" maintained by the government, i.e: the harbor waters. So the carfloating system remained in use.

.

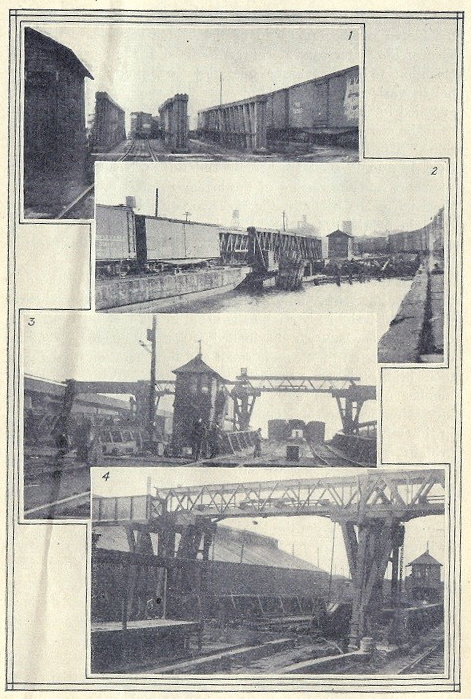

The first intensive use of the dedicated carfloating of freight in the United States seems to have occurred during the Civil War, when freight cars were floated on makeshift barges along the Potomac River, to serve places where existing rail lines could not reach for various reasons. As published in "American Railroad Freight Car", by John H. White, Jr. (1993, Johns Hopkins University Press) credits Brigadier General Herman Haupt for first carfloating on a barge in 1862, during the Civil War. In the October 2000 issue of "Model Railroader" magazine, p. 82-85 there is an illustrated article on the November 1862 construction, under the direction of Brigadier General Herman Haupt, of a carfloat operation for the Union Army at Alexandria, Virginia.

Haupt had been the Chief Engineer of the Pennsylvania Railroad and was in the process of constructing the Hoosac Tunnel when he was "conscripted" to run the U. S. Military Railroad. Two steamtug drawn floats were constructed, each holding 8 cars transversely, and they were served by triple-track aprons at the transfer landings, running from Alexandria, Virginia, down the Potomac River 60 miles to Aquia Landing, about 10 miles northeast of Fredericksburg, Maryland.

In addition, George Abdill on page 48 of his book "Civil War Railroads: A Pictorial Story of the War between the States, 1861-1865 "(1961, Indiana University Press) calls it "pioneer car ferry" which it was not. Instead, it was the pioneer carfloat in the United States.

General Haupt supervised the construction of these transfer bridges at both terminals of this proposed water route. General Haupt also designed, requisitioned materials and built the unique railroad float barges. The carfloats consisted of two large-sized Schuylkill type barges moored side by side, across both of which long timbers were placed supporting eight tracks mounted transversely (from port to starboard instead of the modern configuration of bow to stern).

At Alexandria, VA; the loaded freightcars were placed singly aboard each of the eight tracks of the carfloat. The carfloat was then towed sixty miles by steam tug to Aquia Landing, VA. Once at this location, railroad crews unloaded the carfloats by pulling the cars.

We were able to locate three images of the operation in searching the web. All three images are attributed to the National Archives, but were located on a very nice website showcasing Bernard Kempinski's "The American Civil War in Miniature"..

|

|

Haupt, whose first name was sometimes spelled Hermann, was born in

Philadelphia, Pennsylvania, on March 26, 1817, the son of Jacob and Anna

Margaretta Wiall Haupt. Jacob, a merchant, died when Herman was 12 years

old, leaving Anna to support three sons and two daughters. Herman worked

part-time to pay his school tuition, then in 1831 was appointed to the United

States Military Academy at the age of 14 by President Andrew Jackson. He

graduated in 1835 and was commissioned a second lieutenant in the 3rd U.S.

Infantry that July.

He resigned his commission on September 30, 1835, to accept an appointment under Henry R. Campbell as an Assistant Engineer engaged in the surveys of the Allentown road and of the Norristown & Valley Railroad, which opened in 1835 and 15 years later merged into the Chester Valley Railroad. At 19, he was appointed Assistant Engineer in the state service and located the line from Gettysburg to the Potomac across the South Mountain which was then part of the Western Maryland. On August 30, 1838, in Gettysburg, Pennsylvania, he married Ann Cecelia Keller, with whom he would have seven sons and four daughters. In 1839, he designed and patented a novel bridge construction technique known as the Haupt Truss.Two of his Haupt truss bridges still stand in Altoona and Ardmore, Pennsylvania, both from 1854. From 1840 to 1847, Haupt was a professor of mathematics and engineering at Pennsylvania College. He returned to the railroad business in 1847, becoming a construction engineer on the Pennsylvania Railroad, and then general superintendent from 1849 to 1851. He was the chief engineer of the Southern Railroad of Mississippi from 1851 to 1853, and the chief engineer of the Pennsylvania Railroad until 1856; in the latter position he completed the Mountain Division with the Alleghany Tunnel, opening the line through to Pittsburgh. He was the chief engineer on the five-mile Hoosac Tunnel project through the Berkshires in Western Massachusetts from 1856 to 1861. From the spring of 1862, (after commencement of the Civil War), the United States War Department organized a new bureau responsible for constructing and operating the military railroads in the United States. On April 27, Haupt was appointed chief of the bureau by Secretary of War Edwin M. Stanton, with the rank of colonel and as an aide-de-camp to Major General Irvin McDowell, then in command of the defenses of Washington, D.C. Colonel Haupt repaired and fortified war-damaged railroad lines in the vicinity of Washington, arming and training railroad staff and improved telegraph communications along the railroad lines. Among his most challenging assignments was restoring the strategic Richmond, Fredericksburg and Potomac Railroad line, including the Potomac Creek Bridge, after its partial destruction by Confederate forces. With an inexperienced workforce and other serious impediments, Haupt had the line back in use in under two weeks. After his service in the Civil War, Haupt returned to railroad, bridge, pipeline, and tunnel construction. Haupt died of a heart attack at age 88 in Jersey City, New Jersey, stricken while traveling in a Pullman car named "Irma" on a journey from New York to Philadelphia. He is buried in West Laurel Hill Cemetery in Bala Cynwyd, Pennsylvania. |

|

|

|

|

| . | ||

|

|

||

|

The wharfs and transfer bridges at Alexandria, Virginia.

All four photos:

|

||

.

Once the freight cars were unloaded, they were then able to forward those freight cars with their contents, without the need of "breaking bulk" (unloading the freight from the car) along the rebuilt rail line of the Richmond, Fredericksburg and Potomac Railroad to Falmouth, across from Fredericksburg, VA; on the north bank of the Rappahannock River.

According to Haupt this was:

"the first known attempt to transport cars by water with their cargoes unbroken. The Schuylkill barges performed admirably and thus was formed a new era in military railroad transportation. The length of the barges were sufficient for 8 tracks carrying eight cars, and two such floats would carry the sixteen cars which constituted a train."

All of this construction occurred over a period of two weeks. Haupt was ready to support further military operations by November 17th, 1862. As to how the cars were loaded onto the barges, the technology was already in place for carferrying. So the Civil War usage of carfloating maybe was more of an inspiration than an invention, inspiring the New Jersey railroads about how to serve Manhattan without having to unload everything out of the cars onto ferryboats or sail lighters on the Jersey side.

.

.

Carfloating Comes to New York

Harbor

The first mention of carfloating in New York Harbor can be read in the (Trenton) Daily State Gazette, November 13, 1866, p. 3:

"CENTRAL RAILROAD: The Central Railroad Company [of New Jersey] are having a large scow constructed for the purpose of conveying the freighter cars directly from Communipaw to the New York side. It is large enough to hold eight cars which will be run in on rails from the track on this side. It will be in operation next week. The Western mail which has heretofore been carried by the Erie Railway has been transferred to the Central Road."

.

While this article does state fact, it turns out that there were forces behind this operation that were more complex than simply mentioned here. In fact, the Pennsylvania Railroad was the real sponsor, even though at the time its own tracks came nowhere near New York Harbor!

As read in "History of the Pennsylvania Railroad", by J. Elfreth Watkins, 1896; the Empire Transportation Company's line was organized in 1866, it wished to deliver to Manhattan and since the Pennsylvania Railroad did not reach or have a terminal at that location, it contracted with the Central Railroad of New Jersey, which did build the first carfloat for that purpose. Early in 1867, the operation began with the first carfloats carrying those freight cars across the Hudson River. The "car-ferry" route was from Communipaw, NJ Terminal to Pier 14, on Manhattan's west side, which was occupied at the time by the Central Railroad of New Jersey.

By this method, the Empire Transportation Company was able to load & unload its freight cars at Pier 14 in New York City and transport said freight to its destinations without the need to "break bulk". Arrangements were then made by the Union Railroad and Transportation Company with the Camden & Amboy Railroad and the New Jersey Railroad & Transportation Company for hauling these freight cars through Jersey City, instead of unloading the freight in New Jersey, and transporting it via steamboat between South Amboy and Pier 2 in Manhattan, which had been the existing procedure.

Now this explanation clarifies why both the Central Railroad of New Jersey and the Pennsylvania Railroad have taken credit for the first carfloating operation, and why both have been stated in various sources that they served Manhattan's Pier 2. Furthermore, this explanation coincides with the mention in the Trenton Daily State Gazette.

This history of the Pennsylvania Railroad as cited above, had been compiled for several years by people at the railroad; but it was never actually published. It was supposed to have been published in 1896, and apparently was not changed after that date. So unfortunately it is not easy to consult the original text.

At this point we might as well explain the role of those "Lines" (joint lines) that were the means by which freight was expedited between distant terminals in the days before the railroad system itself was fully integrated. A modern day comparison would be the way we send our packages to some foreign destination by using a courier such as UPS or FedEx. Instead of our (the individual) having to deal and coordinate with the airlines and various trucking companies, we contract a firm such as UPS or FedEx which does all this for us as their line of business. Most of the "Lines" were jointly owned by the railroads involved. They were subsequently "branded" with distinctive names for advertising purposes, as the "Empire Line".

.

John Henry Starin's contribution (or lack there

of?)

Now, from time to time, the name John Henry Starin seems to be attributed to carfloating. At first it appeared he was significantly involved in the development of carfloating in the New York Harbor area. His obituary as it appeared in the New York Times dated March 23, 1909; reads:

"He originated the idea of transporting freight cars on floats, and was very proud of this achievement..."

This might be a bit of an overstatement

however, as it should be noted from historical references, that car ferry

service preceding the development of carfloats. Car ferries, from my

understanding, appeared to be predominately for the transport of passenger

cars, while carfloats were simple utilitarian affairs for freight

cars.

.

| As principal owner of Starin City

River & Harbor Transportation, many references reflect that he became

especially involved with the freight handling, lighterage and carfloating

operations of the Delaware, Lackawanna & Western Railroad.

He also was significantly involved in the lighterage for the New York Central & Hudson River, Morris & Essex and Central of New Jersey Railroads. By the late 1800's; Starin's marine fleet consisted of over 125 tugboats, lighters, steamers, barges and other assorted pieces of marine equipment. However, from established historical resources show that carfloating existing before then. Did Starin simply bring the idea of carfloating from another port and implement service in New York Harbor? Or did he standardize track and toggle positions between the various railroad's carfloats and float bridges, so that one railroad's carfloat could be moored at any other railroad's float bridge? It appears this credit to Starin for inventing carfloating seems to stem from family biographies, which also attribute Starin for almost everything new in the marine world. So unfortunately at this point it appears that the claim of Starin originating the idea of carfloating seems to embellishment and / or overzealousness of family members. Starin's true contribution, if any; to New York Harbor carfloating seems to have been lost (at least temporarily). |

John Henry Starin |

.

.

Introduction to Transfer

Bridges a/k/a Float Bridges of New York

Harbor

| Overview | Float Bridge Types | Design Requirements | Float Bridge Appliances |

| Carfloat / Float Bridge Interface | Float Bridge / Land Interface | A Popular Misconception | Idler / Reacher Cars |

| Bridging a Carfloat at a Pontoon Type Float Bridge | Bridging a Carfloat at an Overhead Suspended Transfer Bridge | Drilling a Carfloat | |

...

..

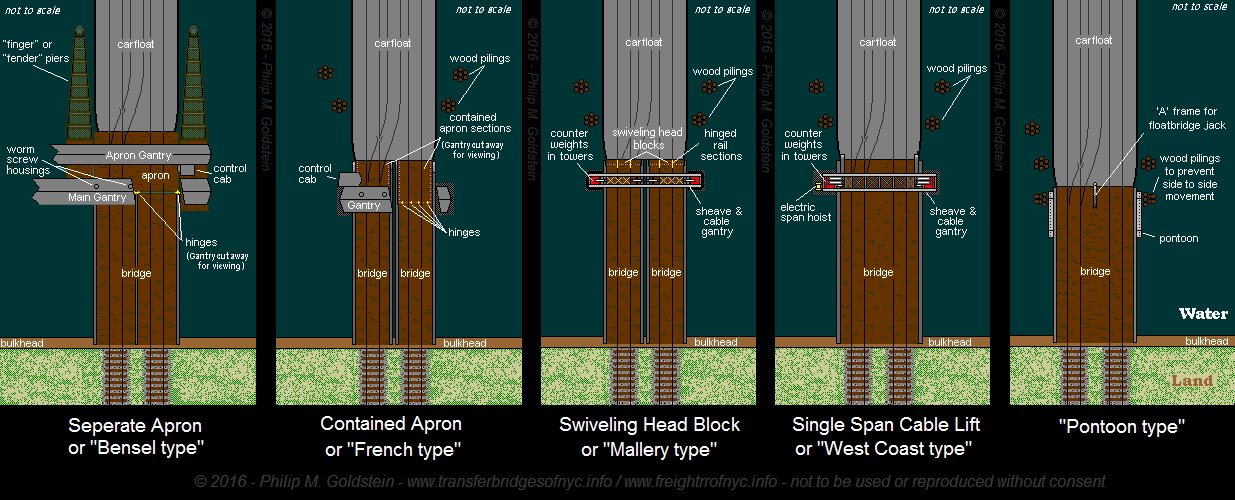

"Transfer bridge" is the general name for the type of bridge that allows running railroad cars directly between land and a boat. This term was used by the engineers who designed them but the term used by railroad workers varied; different regions had different names, as well as distinctive designs. At the Port of New York they were often called "float bridges", and they were here in abundance: through the first half of the 20th Century, there were around 80 or more active bridges. Even during the midst of the Depression, over 5000 cars per day were handled via carfloat in the harbor, according to the National Geographic for November, 1936! The three best known kinds of float bridges at New York (Fig. 1) closely paralleled those at Philadelphia, and were similar to those at Baltimore and Boston. The float bridges of Great Lakes and Western designs were different.

Most descriptions of the designs that have been come across in engineering journals described innovations at Port of New York, as though all the pioneering was done there. That may simply reflect the bias of the journal editors of the time as most were headquartered on the East Coast. On the other hand, the pressure to improve them was greatest in New York, because here they were absolutely vital to the functioning of the terminal.

The Port of New York is geographically an archipelago, with water channels separating densely built up land areas, a situation that forced the railroads to terminate freight for the port over water instead of laying rails on a land, creating a kind of "water belt line" system. Without this flexible system, New York would not have been the leading port in the United States (handling 40% of U.S. foreign trade during most of the railroad era). Moving railroad cars around on the water was one of the primary marine operations here.

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

A float bridge is basically a bridge span anchored and hinged to land on one end, and hung over or supported by the water on the other. The end over the water could be supported by an overhead gantry carrying cables to counterweights to support the dead load weight of the float bridge, as in the case of the Separate Apron of "Bensel" type, Contained Apron or "French" type, Swivelling Head Block or "Mallery" type or the Cable Lifted Single Span "West Coast" type.

The type supported by a pontoon in the water which kept it afloat by buoyancy was simply known as (what else?) Pontoon type.

Both the Separate, Contained Apron and Cable Lifted Single Span designs feature electrically controlled motors for lifting and lowering the bridge spans, as well as for the contained apron design and both the bridge and apron spans for the separate apron type.

The "Mallery" and the early "West Coast" types were manually raised and lowered via counterweights and chain fall system.

The pontoon could have a lightweight overhead gallows with a block & tackle / chain fall or a manually operated hydraulic piston for raising.

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

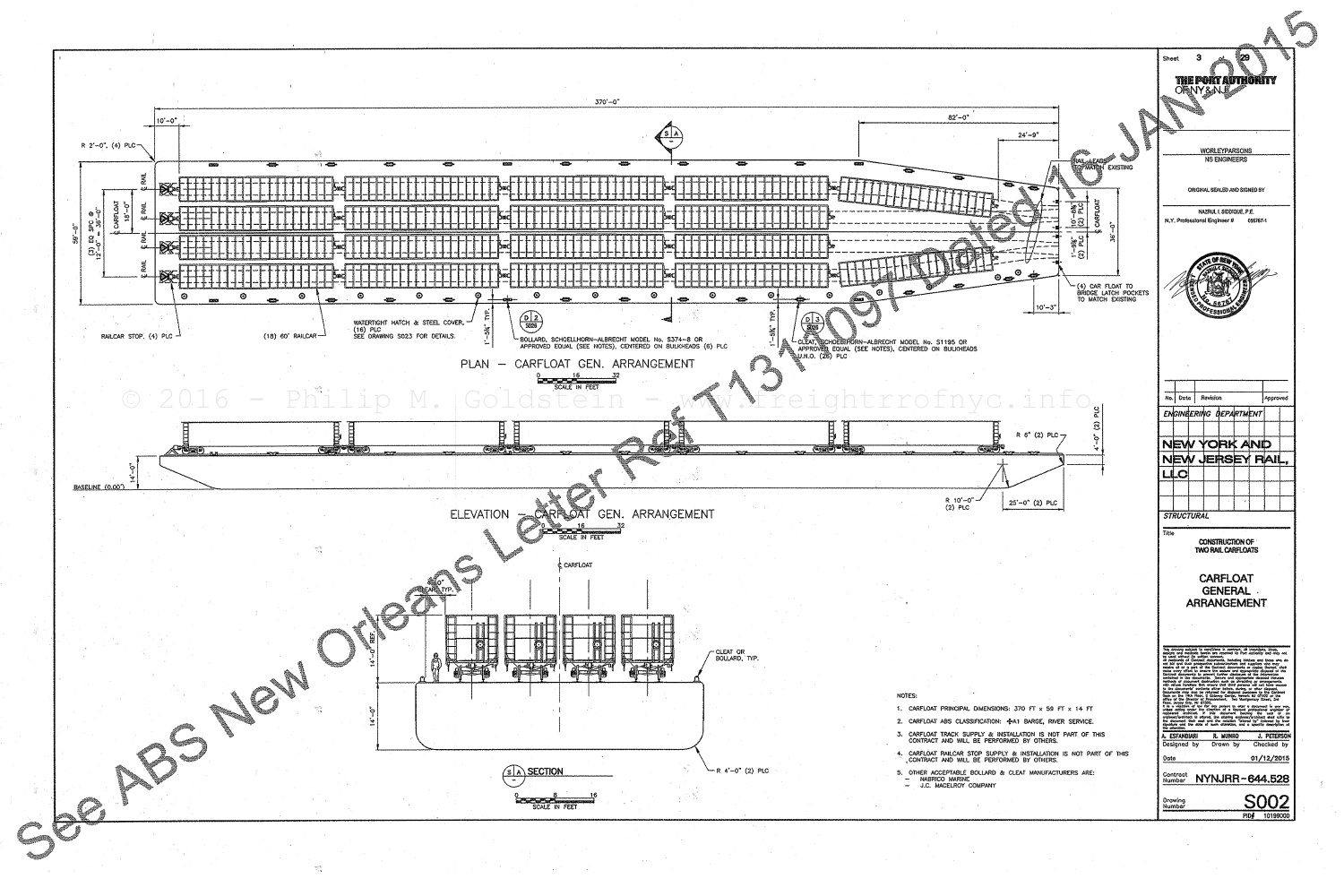

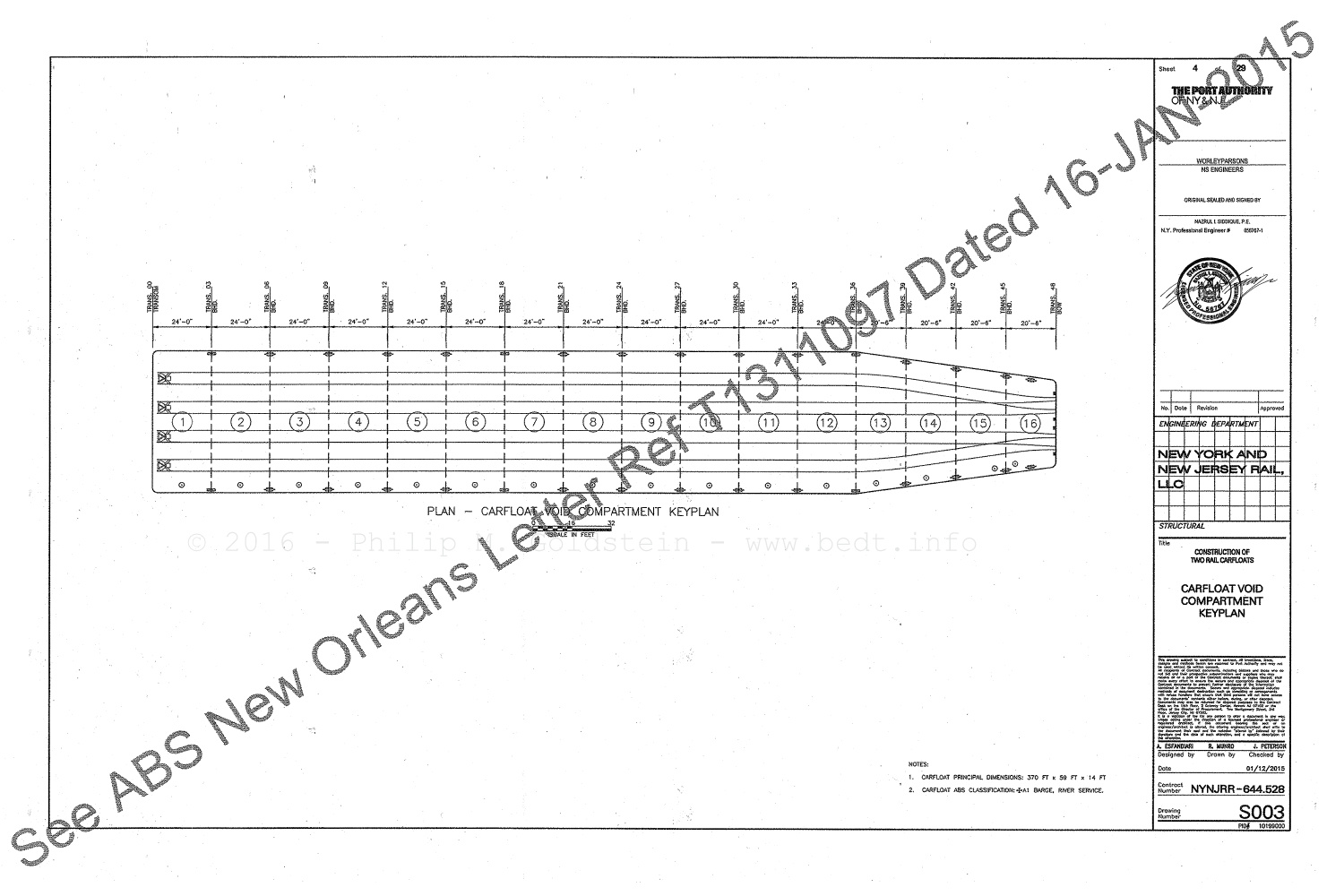

The carfloat itself is not a complicated craft, since it is towed around by tugboats and thus needed no machinery. It is simply a strongly built rectangular barge fitted with tracks. Originally it was constructed of wood with a capacity of 8 cars on two tracks; in later years it would be made of steel, and some of them reached lengths of 320 to 360 feet with a capacity of about 22 cars on three tracks. By about 1900 they were standardized to the point that any float bridge could handle any railroad's float, at least in New York.

Providing a continuous line of track between land and carfloat was a bigger engineering challenge. A "transfer bridge" or "float bridge" not only has to have the strength of a regular bridge but also has to meet requirements that other kinds of bridges do not face.

One of these is vertical motion at one end. While the inshore end of the bridge must be at a fixed height, the water or outshore end must be able to rise and fall. The typical daily tidal range is 5 to 6 feet, with an extreme range of about 11 feet (Engineering News, 1911), though in the most extreme conditions (i.e.: storm surges) operations are simply suspended. In addition, the load on the carfloat determines the free board. Some empty floats might have rails as much as 8 feet above the water, while the heavily loaded one might have rails only 1.5 feet above. The overall operating range at New York was generally taken to be 17.5 feet. (French, 1917). Note also that for a bridge a length of 100 feet (typical at this port), this range would give a maximum rate of 8.5% up and 8.5% down from a midpoint giving the switch engine some real work to do.

A second design challenge is torsional stress. During the loading and unloading, a carfloat lists to one side or the other, requiring twisting motions unknown in normal bridge service:

Pontoon / Howe Truss Float Bridge at Erie Railroad

West 28th Street Freight Station, Manhattan, NY - 1910

Pier 67 to left - looking west.

New York City Department of Docks photo

T. Flagg archives

added 03 January 2012

.

This motion must be taken up somewhere in the structure since at the shore end there can be no twisting. This twisting also puts great difficulties in the way of the float bridge designer who tries to suspend the outer end of the bridge from any rigid support such as a lifting screw.

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

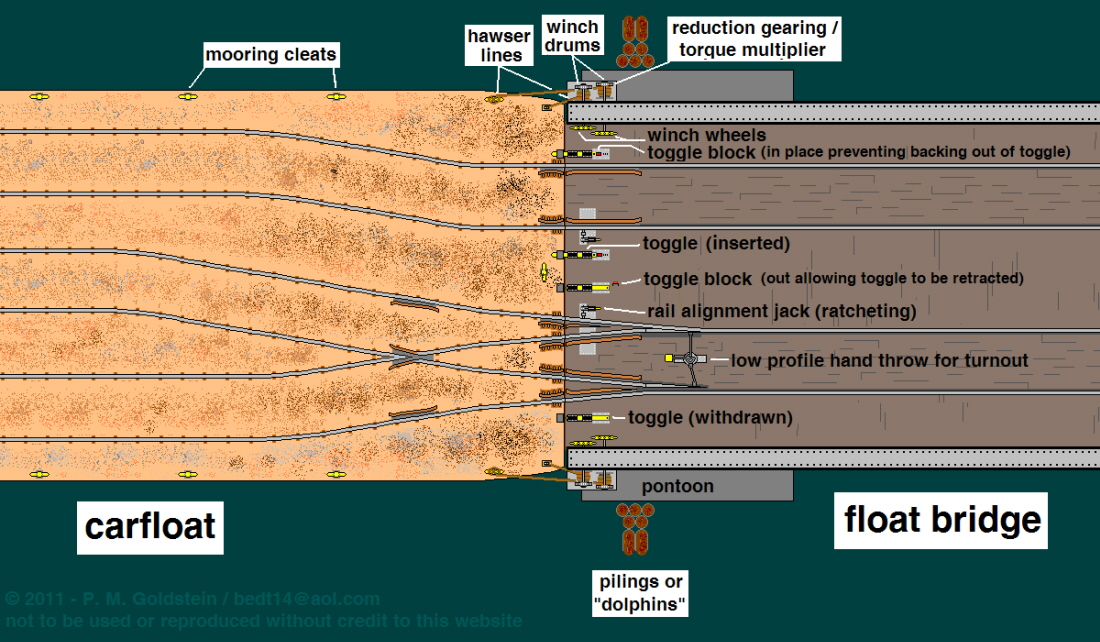

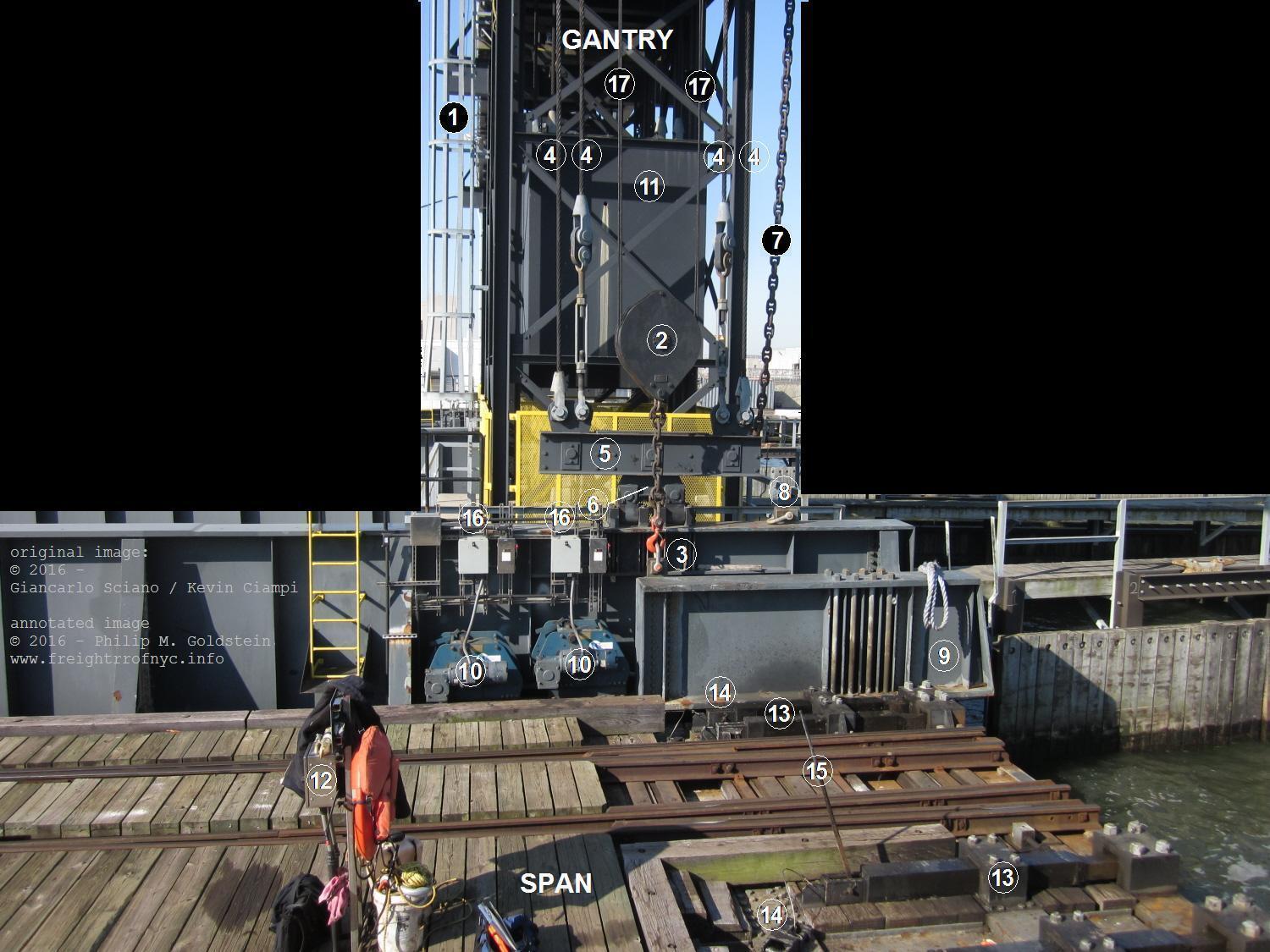

The illustration below shows the appliances found on almost all float bridges used throughout New York Harbor. Clicking on the illustration below will bring you to close up of the appliances. Use the back arrow on your web browser to return you here. For the most part, other than the obvious difference being the pontoon versus the overhead counterweighted suspension types ; the only differences between the manual pontoon type float bridges and the electrically operated overhead suspended type transfer bridges were the main winches were powered by electric as well as the lack of float bridge jack (of which wasn't needed as the span & apron height were electrically controlled) on the overhead suspended types of transfer bridges.

In the image below, a pontoon type is shown. Please take note that the only appliance not shown is the float bridge jack and a-frame. The reason for this is that this component has not been used in day to day float bridge operations for the last 20 years. Matter of fact, by referencing current images of New York New Jersey Rail float bridge operations in Brooklyn, the float bridge jack is not even mounted on the Bush Terminal float bridge in service.

This appliance, if it were to have been included in the diagram below, would have been located between the center two toggles with the hydraulic piston overhanging from the edge of the float bridge.

DIAGRAM NOT TO SCALE

|

.

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

Float Bridge

and Carfloat Interface

On all bridges at the Port of New York, the left track (as one looks from land to water) splits into two tracks just before the edge of the bridge. The bridge contains the "point" portion of the railroad track switch; while the "frog" portion is located on the deck of the carfloat, on those interchange type carfloats containing three tracks. The switch begins 23 feet 9 inches back from the outshore end of the bridge, and the diversion tracks are separated 18in. at the end of the outshore end of the float bridge giving a frog number of approximately 16 (Engineering News, 1911, 773).

Carfloats containing only two tracks (such as station or platform carfloats) simply continue the left track only. Plans and photos from the 1880's and early 1890' do not show this frog; the arrangement apparently came into use at New York about the turn of the century. John Droege (1912, 225), in his description of transfer bridges said it was standard. There is some suggestion that the Pennsylvania Railroad started this arrangement and forced its acceptance as a standard (duBosque, 1915).

Carfloats are held in proper alignment with the float bridge in two ways: they are held snugly to the bridge with heavy rope or lines ("hawsers") and with toggle bars.

To keep the carfloat from moving away from the face of the float bridge, heavy cables or ropes (hawser lines) are used. These are winched tight with the winch wheels seen on the float bridge. It is all too often stated that these wheels on the float bridge are to control pumps, to flood or empty a pontoon but this is simply incorrect. The lines are denoted in the diagram above as #15. At the ends of these lines were steel hoops which placed around their cleats on the carfloat. Today, the line itself is braided into a loop.

Each transfer bridge has either four or six toggle bars contained in sockets. When the bridge and carfloat are correctly aligned horizontally with one another, the "toggle bars" (#16 & 17 in diagram above) are slid into corresponding toggle receptacles (#18) mounted on the end of the carfloat. The toggle bars are of alloy steel and were originally 5 inches square in cross section and 7 feet long (Snow, 1901), but a later revision has these toggles manufactured with a 7" cross section. They were slightly tapered at the point to facilitate ease of sliding into the receptacle on the carfloat. These are most often moved with the aid of a long pry bar. (Once all the toggles are extended into the receptacles on the carfloat, the carfloat can be kept in lateral and vertical alignment to the float bridge.

Under the toggle bar as part of the fixture mounted into the deck of the float bridge are rectangular notches. These can be seen in the patent file by James B. French (but this design existed before this). A steel block with a grab handle on top and studs on bottom was then placed behind the toggle bar, thereby locking the toggle bar it into position, after it was extended into the carfloat toggle receptacle. This prevented the accidental backing out of the toggle bar. The studs on the bottom of the block fit neatly into those notches in the toggle bar fixture. In addition, final adjustments of the lateral position of the rails at the outer end of the bridge, is accomplished with a ratcheting handle attached to a screw arrangement (Fig. 5, 8A, 8B). This device allows adjustment for small differences in rail positions on different carfloats.

After this was accomplished, the lines were given a final tightening via the winch wheels.

..

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

Float Bridge &

Land Interface or "Bulkhead

Anchors"

.

|

|

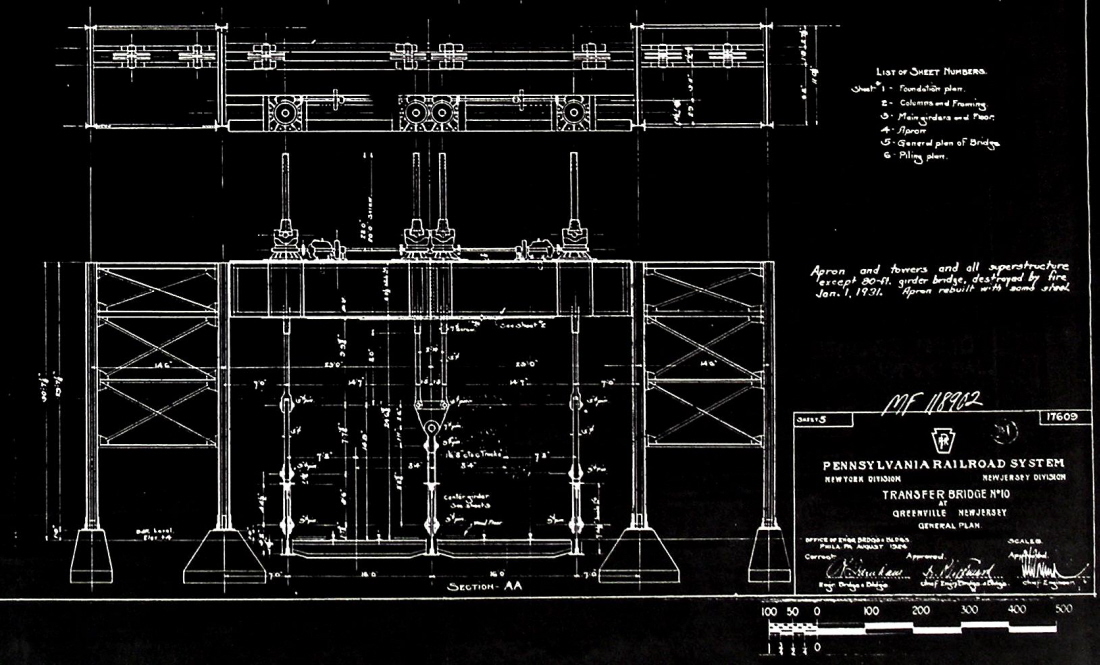

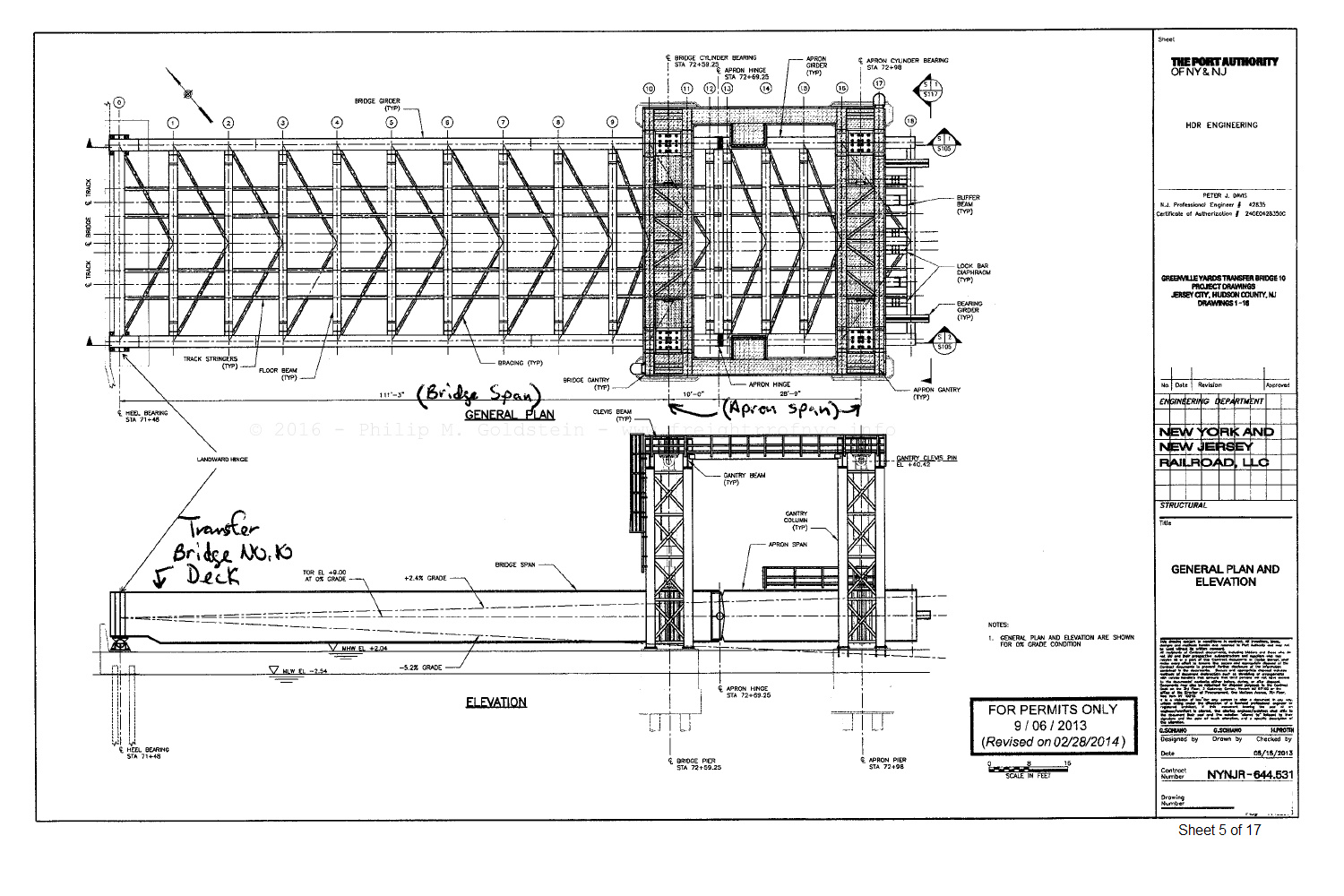

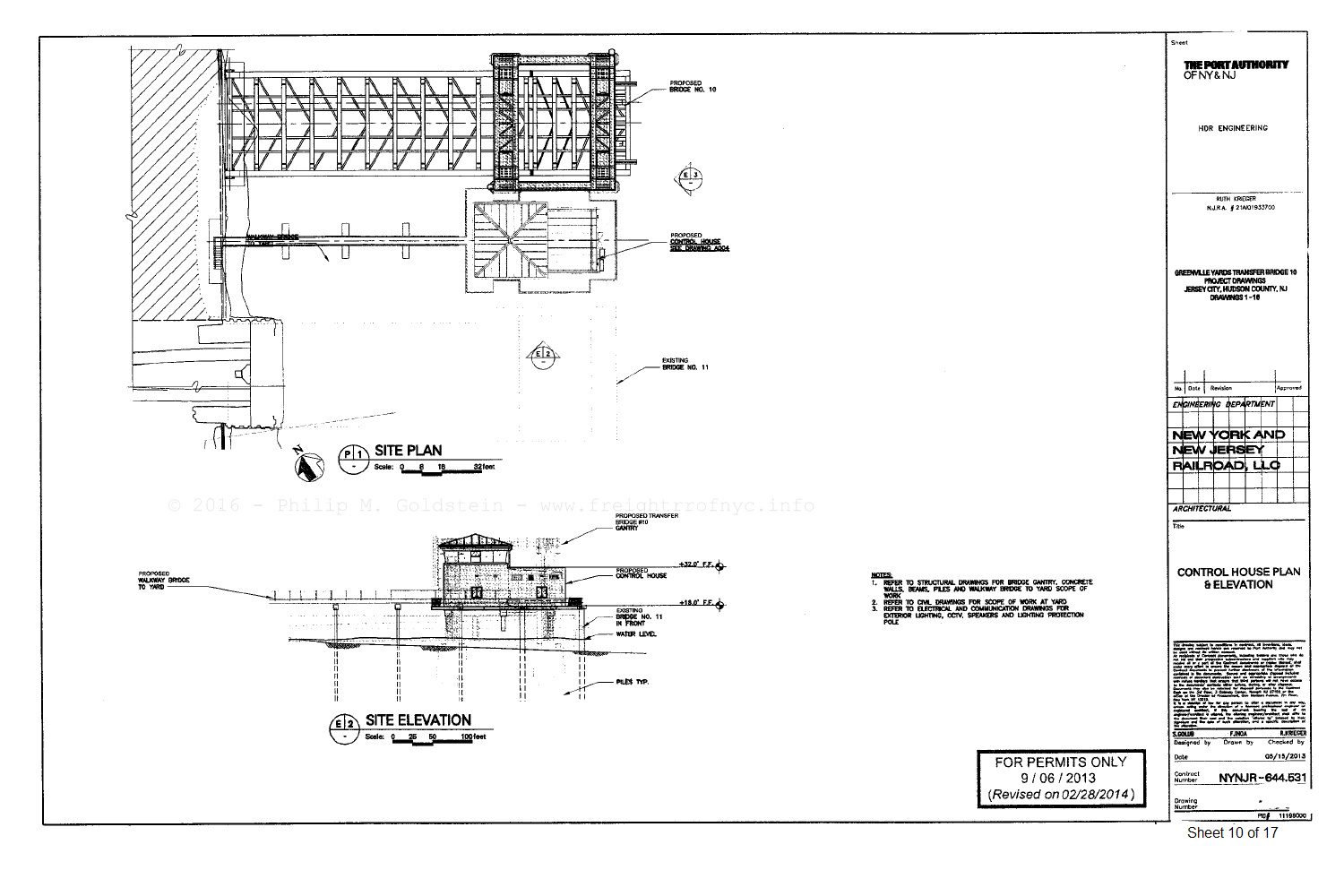

To keep all types of float bridge spans secure to the bulkhead,

they had to be secured in a way that prevented them from floating away or

pulling away from the bulkhead, but still allowed them to pivot vertically.

Wood Howe Truss In regard to the earliest designs of wood Howe truss float bridges, the inshore end of the float bridge had a round log mounted transversely to the bottom of the deck. Wrapping around the circumference of this log and the exposed ends was steel banding or sheet metal to prevent the splitting and separating of the log. On the bulkhead, there was wood blocking with a concave portion carved out to receive the rocker log. This was in effect a cradle. The rocker log was set into the cradle and pivoting was not hindered. As far as can be told, the rocker log type anchor was only used on Howe truss float bridges. Steel Pony Truss or Through Plate Girder With steel bridges there were two designs of float bridge anchor. With advent of steel casting, a newer apparatus was designed. Working on a similar principle to the rocker log, the pivot wheel & box anchor was created. The semi-circular pivot wheel was set into a cast box. The other method was a pin and plate. Both of these can be seen below. Ironically, both of these anchor methods were used at the same facility at Greenville, NJ. The pivot wheel & box design is in place on Bridge #11 (the only transfer bridge at this location which is in operation) and the pin and plate method is on Bridge #10. These differences are attributed to the bridge designer who is contracted to build the bridges: Bridge #10 (out of service) and was built by McClintic - Marsh was headquartered in Pittsburgh, PA. Transfer bridge #11 was built by American Bridge Company of Coraopolis, PA. |

|

|

|

Pivot Rocker & Box Anchor

|

Pin & Plate Anchor |

both photos by P. M. Goldstein - May 2009

Greenville, NJ

added 04 January 2012

.

..

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

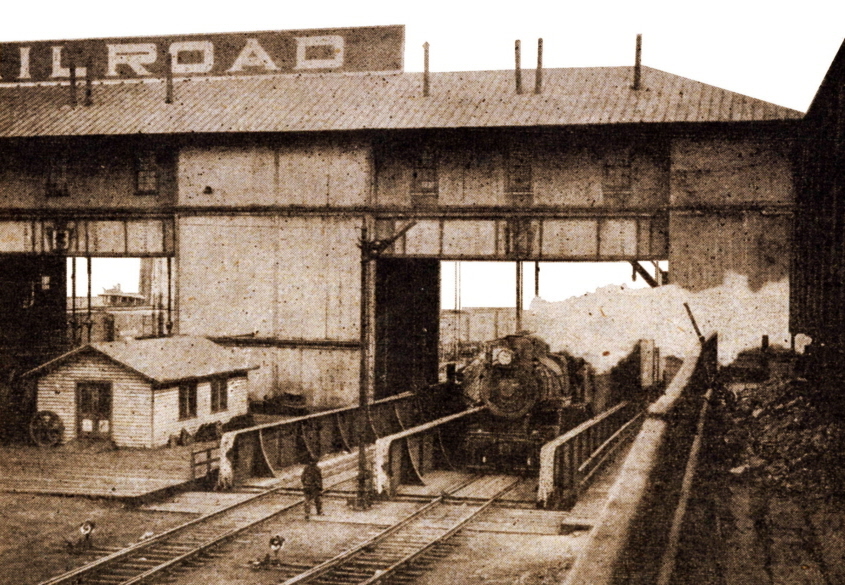

The following statement is repetitiously heard in both prototype railfan and scale modelling circles:

"The locomotive is never placed on the float bridge or carfloat".

.

This statement, quite simply; is incorrect.

Furthermore it is doubted that this practice in general was ever "prohibited" by an actual rule as dictated by a railroad. Research of various Employee Time Tables, locomotive operating manuals, general operations manuals, Rule Books, and/or Marine Rule Books for those Class 1 Railroads having carfloat operations in New York Harbor have failed to show this rule.

Naturally, if anyone can find this rule listed in any New York Area railroads' rule book pertaining to float bridge operation, you are more than welcome to present it and invited to share it here.

However, it would be understood that certain locomotive classes due to wheelbase length or weight may have been excluded from using the transfer bridge, just as would locomotives that exceeded an axle loading would be restricted in using some light branch lines or due to bridge span capacity.

But to have all locomotives banned from setting a wheel on a transfer bridge or carfloat? Not so.

If one refers to the 1910 photo in the "Design Requirements" chapter above, you will clearly see a steam locomotive on the float bridge at Erie West 28th Street. In fact, the Brooklyn Eastern District Terminal would as part of normal operations, repetitively send a locomotive (steam or diesel) on the carfloat along with the freight cars, to its Pidgeon Street Yard or to the Brooklyn Navy Yard.

In the photo below, you will see numerous hoppers full of coal, weighting in at 80-100 tons per car. The lightest thing on the carfloat (besides the empty flat car) was the locomotive (64 tons)!

East River - 1954

#15 aboard Carfloat #22 and enroute to Brooklyn Navy Yard (note loaded coal

hoppers for BNY powerplant).

S. Meyers photo

D. Keller archives

P. M. Goldstein collection

added 24 January 2012

.

Furthermore, any number of images within Tom Flagg's books: "New York Harbor Railroad's in Color", clearly show locomotives of various railroads, weights and sizes on both overhead suspension and pontoon type float bridges and / or carfloats:

Volume 1: p. 25 (CNJ); p. 44 (HT); p. 52 (ERR); p. 55 (ERR); p. 63 (LIRR); p. 107 (BEDT); p. 126 (HS)

Volume 2: p. 19 (BT); p. 42 (EL)

If one further attempts to argue that the locomotives in those images were "lighter switching locomotives", then I refer you to this image: even large heavy switcher type locomotives are seen on the transfer bridges at Greenville, NJ:

Railroad Magazine, September 1945

"Boxcar Navy" by William L. Rohde

appears to be a 'H class' "Consolidation" 2-8-0 which weighed between 220,000

and 247,500 lbs.

added 24 January 2012

.

.

And

here we have a great photograph of a Baldwin built H-10 class

Consolidation on the Long Island Rail Roads' Long Island city Transfer

Bridge #5, taken in 1945. Built as PRR #7205 in November 1913, it

wentto the PRR in July 1928, and weight between 220,000 and 247,500

pounds. This image is significant as the date of 1945; a steam

locomotive in Queens (within the city of New York, and and after 1931

with the Kaufman Law in full effect, and:

Queens Public Library Digital Collection

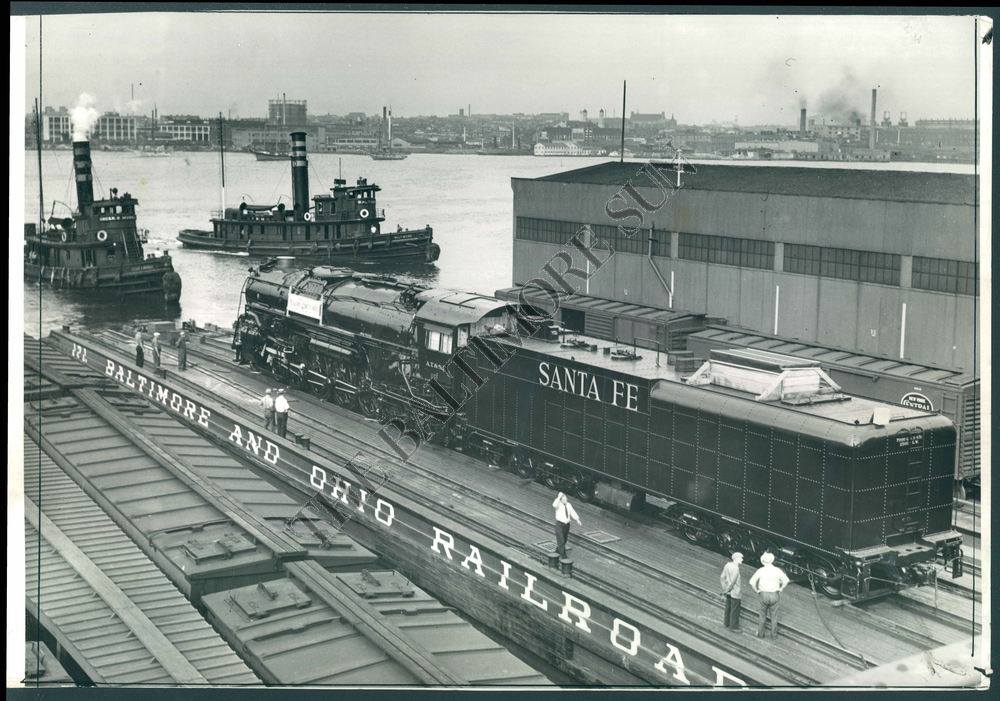

This next image was located on the internet, courtesy of the Baltimore Sun digital archives. It is of Santa Fe (AT&SF) #3829 "Texas" 2-10-4 locomotive on a carfloat, and an older wood hull carfloat at that! The locomotive was constructed in 1919 by Baldwin Locomotive Works, so from the new appearance of the locomotive, that image could be dated accordingly.

The total weight for the locomotive and tender was 679,000 pounds. This locomotive was rolled onto the carfloat, and not hoisted or rigged aboard. This means both the carfloat and the float bridge were obviously able to support its weight.

courtesy Baltimore Sun digital archives

| two ALCo RS3's | NYD #56 & #57 | 247,100 pounds each | 494,200 lbs |

| four GE 44 tonners | NYD #51, #52, #54 and #55 | 88,000 pounds each | 352,000 lbs |

| three ALCo S1 | BEDT #26 and #23 (out of view on the other side of the RS3's) and #24 | 199,000 pounds each | 597,000 lbs |

And, if this photographic evidence is not enough, or the obstinate tries to take the position that those images above were taken in the "older era" of operations, then I ask you then simply to review the following image and / or watch the video at the 7m 45s mark that I took in May 2011 of NYNJ Rail - carfloat mooring & car unloading (first carfloat): Bush Terminal 50th Street "Bush 2" Float Bridge, Brooklyn, NY. In this video, you will witness a 248,000 pound SW1500 diesel locomotive both sit upon and cross the float bridge to board the carfloat to couple up to the freight cars. This takes place in everyday regular operations of New York New Jersey Rail:

New York New Jersey Rail #1133 on Bush 2 float bridge

& Carfloat 16- May 31, 2011

Note the float bridge pontoon is completely submerged on this side.

P. M. Goldstein photo

.

So, um... yeah..

This misconception of "locomotives being too heavy for a float bridge or carfloat" is one of; if not the most prevalent misstatements regarding float bridge and / or carfloat operations.

.

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

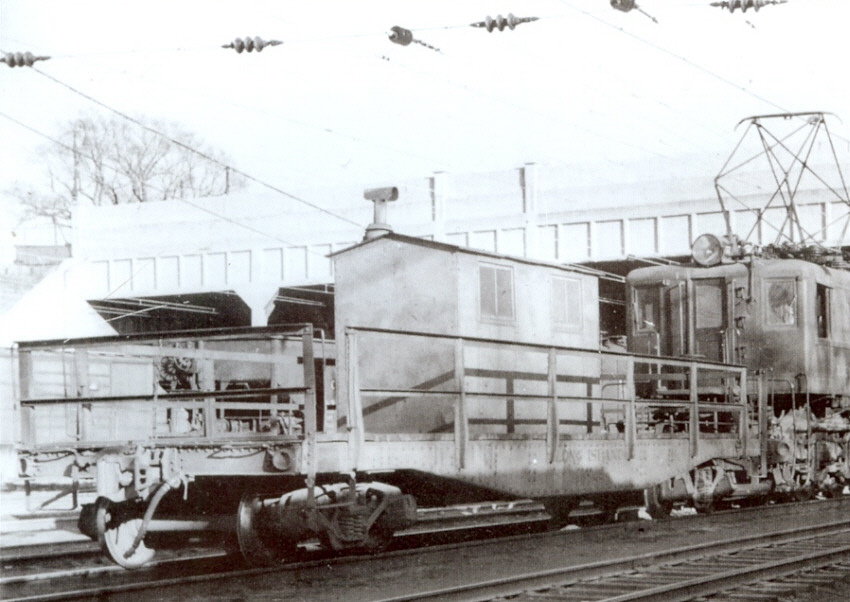

Some railroads, especially the Long Island Rail Road; preferred to use "idler" or "reacher" cars. According to Droege, (1912, 225) the main reason for using idler car when moving freight cars on and off the carfloat, was that often the vertical alignment of the carfloat and float bridge was imperfect, especially when the toggle bars were worn, and that it would be bad to run a heavy locomotive over such a vertical misalignment. The use of an idler / reacher car operation however, was up to each particular railroad and location.

Another factor that required the use of a reacher car can be observed at the LIRR / NYNH&H Bay Ridge Yard. This Yard had the uniqueness of having an electric catenary. As this catenary could only extend to the outshore end of the transfer bridge, and as such; locomotives could not progress past the point and therefore could not enter upon the carfloat to couple onto the freight cars. So, an idler car or two took up the remaining space between the locomotive and freight cars:

Even after the operations of the Bay Ridge Yard switched to diesel electric power exclusively in the 1958, the idler cars stayed in use and presumably as a result of that already established policy. Idler car use did not live for much longer after this with the Bay Ridge Yard closing in its entirety in 1968.

In most cases, idler / reacher cars were made up from gondolas converted for use as a reacher car (ballasted with weight, openings cut out of the sides at both ends for easy entrance / egress, benches for crew and safety handrails) as in the case of Bush Terminal reacher cars #100 or 101; or as in the case of the reacher cars used by the Long Island Rail Road which were quite fancy: a shanty and windows (and a stove!) was mounted to the deck of a flat car, and a waist height railing placed around the perimeter of the flatcar for crew safety.

But in fact, any empty freight car could be pressed into expedient service as an idler / reacher car.

Long Island Rail Road Float Reacher Car - ca. 1958

Note, electric catenary locomotive. Bay Ridge, Brooklyn, NY

F. G. Zahn photo

added 24 January 2012

.

Other railroads did not employ reacher cars: Brooklyn Eastern District Terminal, whether it be the small tank locomotives (64 tons) or diesel locomotives (99 tons); or the New York Dock Railroads' light diesel locomotives (50 tons) at Fulton, Atlantic & Baltic Terminals; which frequently drilled the carfloats without reacher cars, and thus the locomotives had to go onto the float bridge and likewise, the carfloats.

In regard to the modern era of operations, and specifically in regard to the only surviving rail-marine / carfloating operation in New York Harbor: New York New Jersey Rail until late 2016; drilled their carfloats without the use of a reacher car.

As of that date however, it appears two Norfolk Southern gondolas (NS 617759 and NS 617591 respectively) are partially loaded with ground up asphalt pavement and sectional concrete retaining wall blocks a/k/a "mafia blocks " and are being used in regular drilling operatings as idler cars. Then sometimes the sit in the yard unused for months at a time and are not used.

.

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

Bridging a Carfloat at a

Pontoon Type Float Bridge

The skill of the bridgemen makes "bridging a float [carfloat]" as it is actually called in day to day operations, look simpler than it actually is. Signals directed an incoming tugboat to a particular float bridge. These signals could be transmitted via steam whistles, electric horns, flags or lanterns in the early days and two way radio after World War II.

The tugboat pushes a carfloat into place and lines are attached to cleats or bits on each side of the carfloat near the shore and. These lines are then all winched in and tightened with hand wheels or electrically operated power winches to draw the carfloat in flush against the bridge.

The end of the bridge is then adjusted to the height of the carfloat as explained above, and the toggle bars are slid into their sockets on the carfloat. A final tightening of the lines can then be done.

..This chapter, once the reader has familiarized themselves with the components of a float bridge; is to give the reader an understanding of the procedures involved in mooring and pinning a carfloat to a float bridge. This is the procedure for normal day-to-day operations. Rarely, this procedure would be modified to accommodate unique occasions, such as special loads, locomotive moves, etc.

To moor carfloats at pontoon type float bridges;

the following procedure applies:

Tugboat approaches float bridge with carfloat,

and holds it in position for mooring;

(In the earlier era of operations, while the following is taking

place, freight clerks would begin inspection of the freight cars and their

seals at this point too);

Four hawser

lines* attached

to front mooring cleats (two on each side) of carfloat and are tightened

up via winch wheels to bring carfloat into initial

alignment. The winch wheels turn the winch drum (which

holds the hawser line) via a gear reduction / torque multiplier system;

Locomotive slowly proceeds onto right track (facing water) of float bridge to weigh it down into the water; and to match height of float bridge with deck of carfloat;

The right toggle bars are slid into carfloat toggle receptacle and fastened with the toggle bar block;

Hawser lines would be tightened again via winch wheels, and mooring lines from carfloat side cleats are attached to finger pier (if applicable);

Locomotive reverses and backs off float bridge,

switches to left track, and proceeds forward on float bridge left track until

left side toggle bars

are aligned with carfloat toggle receptacles;

The left toggle bars are slid into carfloat toggle receptacles and are fastened with the block;

Hawser lines are tightened again;

Hand jacks on the rails on the float bridge would be turned to adjust the horizontal alignment of the rails on the float bridge to match with rails on carfloat if need be;

Chains and / or chocks are detached from the freight cars, and the brakes are then are released. (Hand brakes spun off in early days at BEDT air brakes were not used.)

Locomotive (with or without idler cars) now "drills"

the float (unloads cars from carfloat). For the procedure on this operation,

please proceed to the next step below:

* Certain locations only had two hawser lines

and two winch wheels (one each side of the float bridge). It is believed

that the four line method was used where there were no fender or finger piers

to help secure the carfloat against lateral motion.

..

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

Bridging a Carfloat

at a Overhead Suspended Transfer Bridge

Carfloat mooring and pinning procedures

were a little different at overhead suspended electrically operated type

float bridges (as opposed to that of pontoon bridges) as these transfer bridges

have electric motor for raising & lowered the bridge span and electric

winches for drawing in the carfloat tight against the float

bridge:

Tugboat brings carfloat in, and the float bridge

and or apron is raised or lowered by the bridgeman in the control cabin to

bring it into correct height alignment with

carfloat.

Hawser lines from power winch attached to front mooring cleats on each side of carfloat.

Carfloat would be drawn in tight to float bridge.

All toggles (pins) would be pried (slid) into carfloat receptacles (toggle boxes) and chocked in place with "toggle block".

Secondary hawser lines from manually powered winch wheels added and tightened.

Hawser lines from carfloat side cleats attached to "finger piers" on both sides of carfloats.

Ratcheting jacks on the rails on the float bridge would be turned to adjust the horizontal alignment of the rails on the float bridge to match with rails on carfloat, if needed;

Locomotive (with

or without idler cars) now "drills" the float (unloads cars from carfloat).

For the procedure on this operation, please proceed to the next chapter below:

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

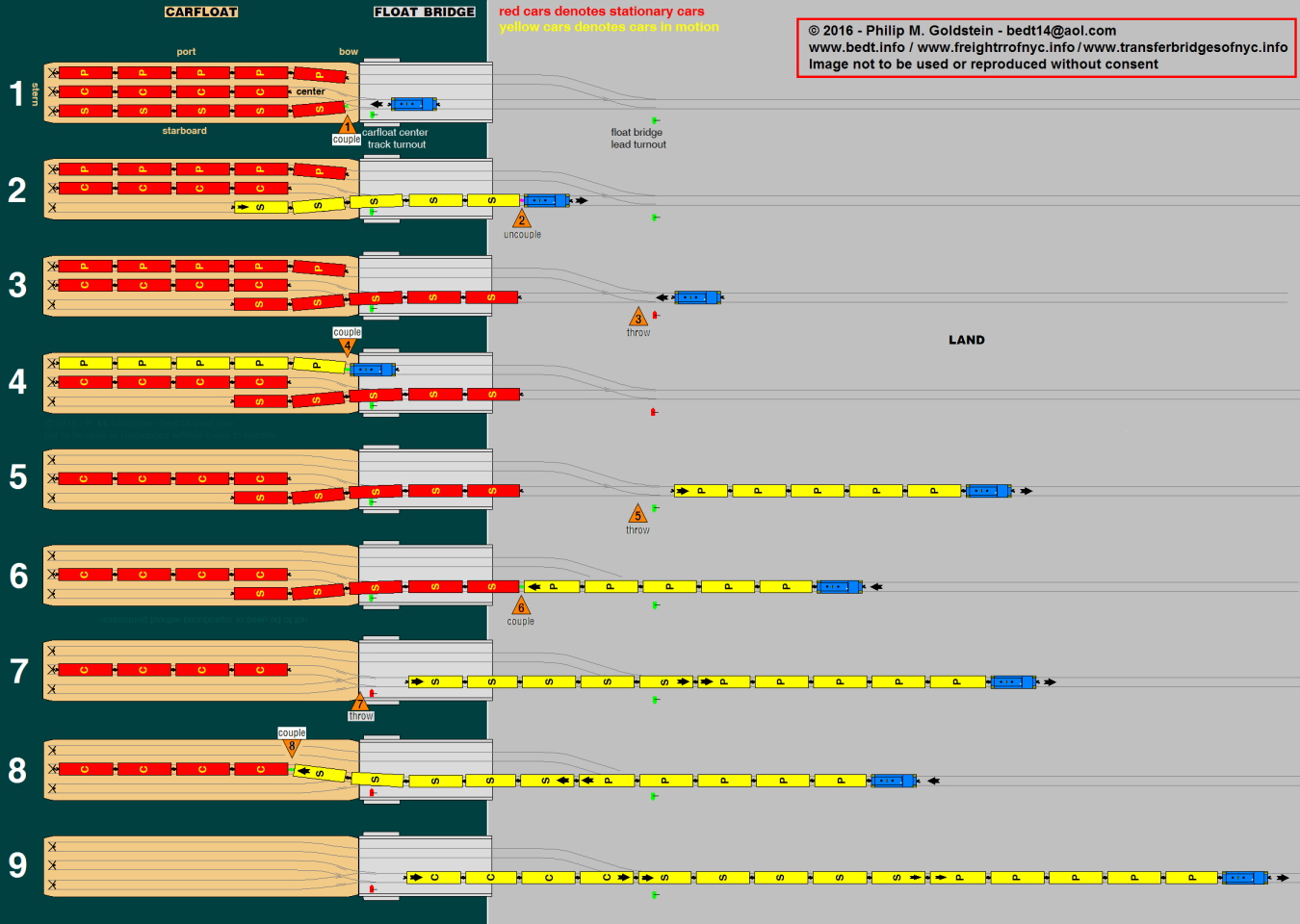

Drilling (unloading / loading)

a Carfloat

The procedure for unloading a carfloat can be viewed below. Please note, this procedure would apply in 99% of the time. In certain unusual cases, the procedure would be modified to accommodate an extra heavy or wide load or special circumstance. While the diagram below shows a pontoon float bridge, the procedure was the same at overhead suspended transfer bridges.

|

|

(Numbers in description correspond to the numbers in illustration.)

Locomotive is inched forward onto float bridge to

bring it into same height as carfloat. Carfloat is secured to float bridge

using method and appliances outlined in above

chapter. Locomotive then couples up to cut of cars on starboard

side track.

Locomotive pulls cut of cars on starboard side track half way off the carfloat and onto the float bridge lead; leaving part of the cut of cars still on float bridge and carfloat;

The locomotive uncouples from starboard side cut of cars, and locomotive continues past float bridge lead turnout. Turnout is thrown and aligned for port side track.

Locomotive heads forward onto port side carfloat track, and couples up to cut of cars on port side track.

Locomotive reverses direction, and pulls entire cut

of cars off of port side track of carfloat and past float bridge lead turnout;

and float bridge lead turnout is thrown and aligned

for starboard side track.

Locomotive proceeds forward pushing port side cut of cars and couples up to starboard side cut of cars.

Locomotive reverses direction and pulls combined port

and starboard side cuts of cars off carfloat to clear the turnout on float

bridge for carfloat center track, and points of

center track turnout are thrown and aligned for center

track;

Locomotive pushes combined port and starboard of cars onto carfloat, coupling up to string of cars on the center track of carfloat.

Locomotive reverses direction, and pulls entire cut

of cars (combined port starboard and center track cuts of cars) into

the yard.

Carfloat is now unloaded. To load carfloat, reverse procedure.

Would you like to see this operation in

real time? Visit my videos on YouTube

at:

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

.

| The Pontoon | Physics & Construction | Design Types |

| The DL&W Gantlet Track | Height Adjustments | Drawbacks to the Design |

| Installations: Tracking the Pontoon Examples | Return to Service: "Bush 2" becomes "Greenville 11" | |

.

The Pontoon type float bridges were commonplace at both large

Class 1 terminals on the New Jersey shore as well as smaller offline terminals.

This float bridge design was affordable, durable, easily maintained and most

importantly, the design worked.

According to French's book "The Development of the Carfloat

Transfer Bridge in New York Harbor" (1917), all float bridges located in

New York Harbor between 1866 and 1888 were pontoon supported Howe Truss

type. Unfortunately, it is not stated which railroad built the

first pontoon type float bridge in New York Harbor.

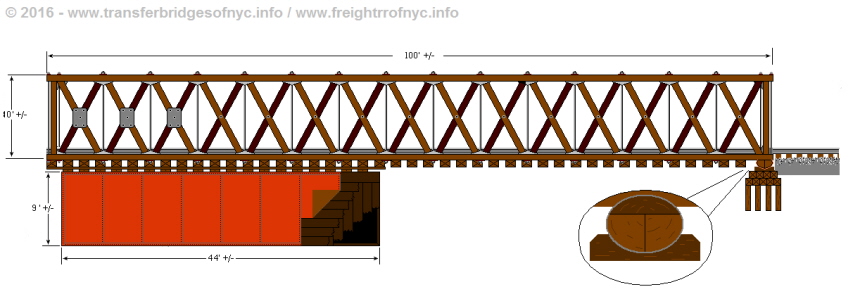

A pontoon type float bridge is nothing more that a bridge span hinged to the land on one end (inboard or land side) and a watertight box under the span at the outer or waterside end. But as simple as that sounds, it was more involved than that.

.

Supporting the outer end of the bridge on a floating pontoon is the simplest method that is both flexible and gives sufficient lift; and it was the first type introduced in the Port, circa 1866 to 1868 (Rohde, 1945; New York New Jersey Harbor Development Commission, 1920 - reference Transfer #10). In 1888 the problems involved in suspending the bridge from an overhead frame were solved by adding an "apron", as we will read in the suspended bridge chapter of this page, but the pontoon bridge was much less expensive and remained popular.

As pontoon float bridges were simple and economical to construct and easy to maintain, they were commonplace and could be found at almost every rail-marine terminal in New York Harbor; large, medium & small. The smaller independent contract terminals of the area relied on them almost exclusively. By the end of the 1970s the remaining operations at the port (with one exception: Greenville) reverted to the pontoon bridge for the sake of simplicity.

In its general appearance the pontoon type of transfer or float bridge does not appear complicated. Most designs average about 30 feet wide and 100 feet long.

The Development of Carfloat Transfer Bridges in New

York Harbor, J. B. French - 1917

Plate I

|

1 & 2: Howe Truss type pontoon float bridges. |

P. M. Goldstein

collection

added 02 January 2012

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

.

Pontoon Physics and

Construction

This pontoon is of course, the key element of the design. In supporting the outshore end of the bridge, it automatically adjusts the float bridge for the tide, but it does much more then this (French, 1917). When the end of the bridge is attached to a carfloat, and freight cars roll over it, there is what engineers call a "live load reaction", meaning the bridge is suddenly called upon to support a much greater load. "Live load" refers to the variable weight on the bridge, as opposed to the "dead load", the weight of the bridge itself. In a properly designed fixed bridge, this force is carried down to the foundations, with little or no movement of the bridge structure.

With float bridges, things are different. If there were no pontoon and the bridge simply rested on the carfloat, all of the load would be applied to the carfloat, which would then sink until reaching a new state of equilibrium between the load and the carfloats buoyancy. But total reliance on the carfloat buoyancy is not advisable: it puts great strain on the carfloat the cause of the concentration of the load on one end, and if the carfloat sinks very far, there will be great strain on the connection with the float bridge due to the sharp angle. Also it could put the carfloat deck below water. And the sinking of the carfloat is uneven since one side is normally loaded before the other; if the carfloat must provide all the support it could list dangerously far. Imagine the scene in if the carfloat had to provide all the support!

Adding a pontoon to the bridge provides the needed additional buoyancy. As more weight is added to the pontoon, it begins to sink, but this additional displacement gives it more upward pressure where needed, automatically. As the load is transferred to the carfloat, it also sinks; the two tend to work in harmony. Thus pontoon bridges are inherently stable (French, 1917).

A pontoon in simplest terms, is a rectangular shaped tank sealed for the purpose of holding air and used in support of a waterborne object. It works by both utilizing displacement and buoyancy.

In the 19th Century, the initial design of the pontoon shown it generally constructed of wood planking caulked with pitch or tar and usually "coppered"; that is sheathed in copper sheets, much like a ship's bottom.

By the 20th Century, as metals took over as a preferred material for construction, the construction of the pontoon would evolve to be of steel plates, with overlapped seams and riveted. As the older wood pontoons reached the end of their service life, steel pontoons would even be used even under both existing or newly constructed wood Howe Truss bridges.

As metalworking technology further advanced in the 20th Century, the steel plates would come to be welded (replacing riveting) and this method remains so today when pontoons are when constructed for an existing and in service float bridge such as Greenville #11.

Graphic representations of the three types of pontoon construction as described above may be viewed under each type of pontoon span in the chapter below. Please note however, that any type of pontoon could have been found under any type of span.

In additions, there must be vertically driven pilings to keep the whole thing in line laterally, with side guides and chafing blocks, otherwise the bridge would float sideways with currents, tides and winds. These pilings are also referred to as "dolphins". Separate pile racks and fenders usually extended out into the river or bay to protect carfloat from floating ice and debris (Snow, 1901, 163).

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

.

Types of Pontoon Float Bridges:

Span / Design Styles

Please note the illustrations below do not show winches, jacks and other equipment, and minor aesthetic differences varied by builder.

.

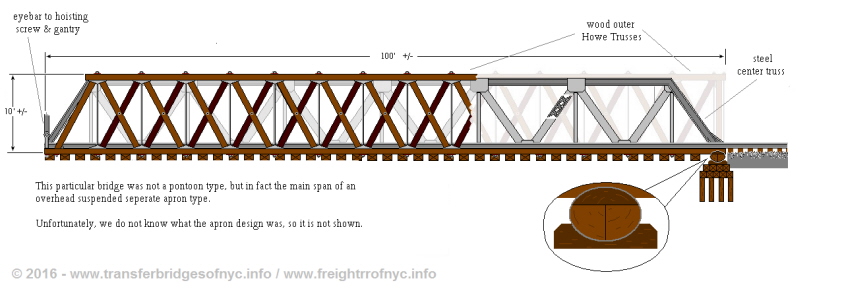

wood Howe Truss

Most 19th Century bridges used three wooden Howe trusses, with a top chord 10 feet above the tracks and the trusses about 16 feet apart center-to-center, with the center truss being midway between the two tracks. Some of the Howe Trusses were covered with vertical siding and caps shaped like gable roofs. This variation was used almost exclusively, at early overhead suspended separate apron locations to keep out the weather. A number of these wooden Howe Trusses lasted well into the 20th Century. In fact, the Baltimore and Ohio Railroad built one in the 1954 as a replacement for a steel girder bridge located at West 26th Street, Manhattan and it is in all likelihood the last wood Howe Truss float bridge constructed in the United States.

Wood was the preferred material by some railroads because of the salt water environment in New York Harbor, and because a wood truss tends to be flexible (Engineering News, 1890).

The bridges themselves were spans of wood Howe Truss design. Hardware such as the winches, toggles, angle braces and threaded rods were made of iron and steel. Three trusses ran lengthwise along the top of the span, with the one span running up the center.

This type of float bridge was found to be ideal for the purpose, as the wood was flexible enough to absorb the torsional stresses encountered during the loading and unloading of a carfloat.

not to scale

.

Constructed with heavy wood timbers and wood decks that were creosoted for protection against decay. Threaded steel rods bound the upper and lower horizontal beams "chords" together and cast iron angle braces bolted to the corners of the diagonal trusses added additional strength.

Early designs used a wood "rocker" log as a hinge point on the bulkhead. This would evolve to a cast steel pivot anchor and socket.

As discussed in the above chapter, the Howe Truss graphic above shows the basics of the very early pontoon construction: wood planks, sealed with pitch and sheathed in copper plate.

By the turn of century, the iron or steel bridge was beginning to replace the wood Howe Truss, as the manufacturing processes for structural iron & steel components gained popularity and abundance. In time the "all wood" design evolved into steel pontoons of riveted or bolted construction and of bridge spans of riveted steel.

These new iron & steel designs would be available in two kinds: pony truss and through plate girder. With both types of steel float bridges, subtypes existed: both can be seen in three-girder and two-girder versions, although three truss float bridges were uncommon. None of these trusses or girders are essentially different from those used in regular bridges, except perhaps for their connections with the floor system. Both types of steel float bridges worked equally well, and were used throughout the New York area.

.

steel Pony Truss

|

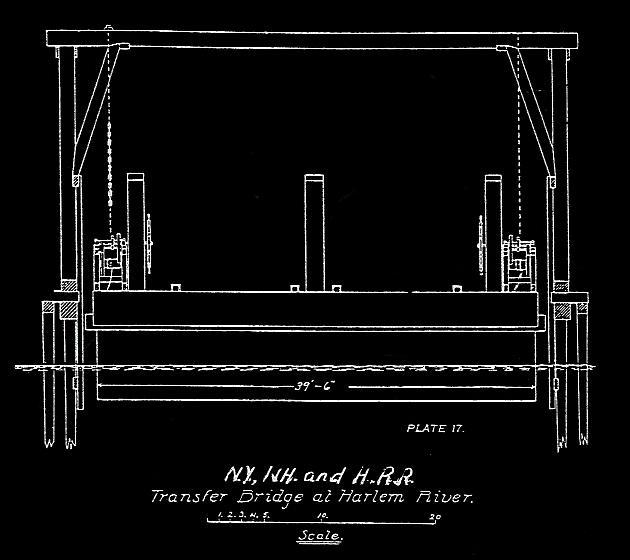

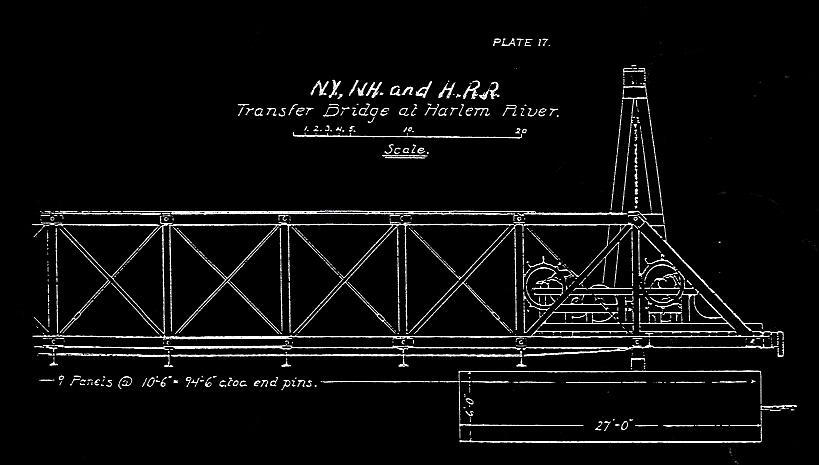

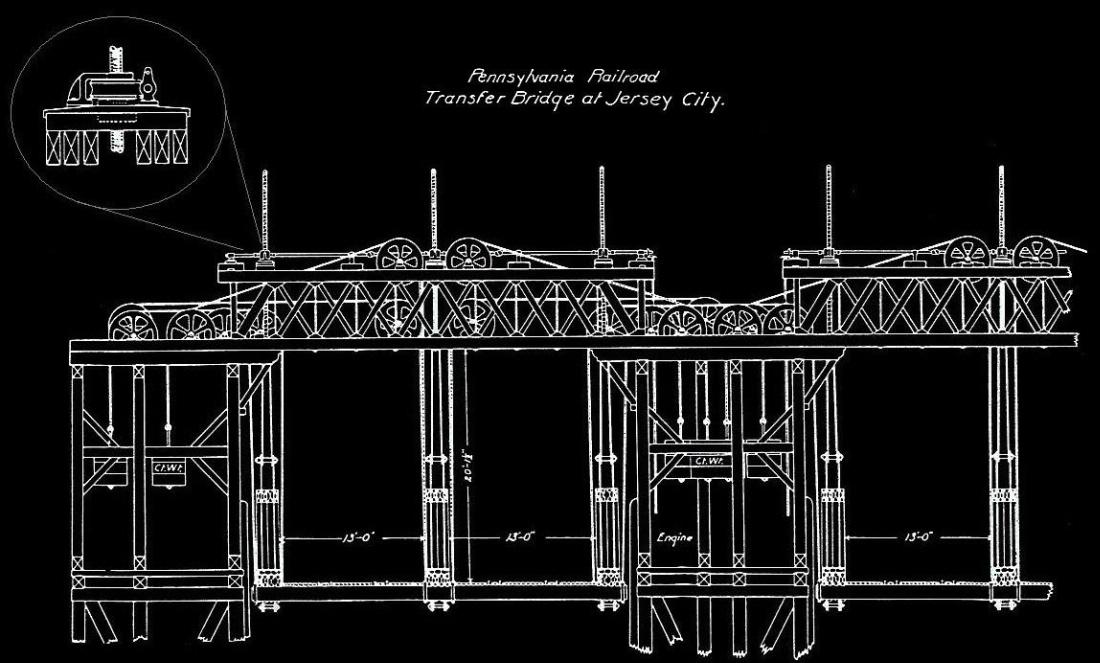

. Toward the end of the 19th Century, steel pony trusses came into favor with some railroads, almost always with two strong outer trusses and no center truss (French, 1917, 60). But there was an exception: the float bridges at the New York, New Haven & Hartford Railroad's Hell Gate location were unusual in their design as they were constructed with a center truss member (making this a three truss subtype). While we have commonly seen a third plate girder installed at the center on the plate girder design type of pontoon bridge, a middle truss was not common on the pony truss. You can see this third truss in the blueprints and images in the Lifting Gallows chapter. Pony Truss and Through Plate Girder types were constructed of riveted iron and steel construction, with wood plank decks. Trusses were approximately 8 feet tall. These designs used steel "pin and plate" hinges or steel "pivot wheel and box" anchors on the bulkhead. Pony truss types also had two design variants: a two truss and a three truss. This means a two truss float bridge had a truss on the outer edges of the float bridge and no center truss. The three truss subtype had an additional truss running up the center of the float bridge between the tracks (like the wood Howe Truss). This pony truss above is shown with a riveted metal (iron and/or steel) pontoon. |

|

| .

.. |

|

|

. . |

|

| Through Plate Girder types also had two design variants:

a two girder and three girder subtype. This means a two girder float bridge

had a plate girder on each of the outer edges of the float bridge and no

center girder. A three girder type had an additional girder running up the

center of the float bridge between the tracks. Girders were usually 4 to

6 feet in height. By far, the Through Plate Girder type was the most prolific

design of pontoon float bridge in the 20th Century.

The Thru Plate Girder float bridge above is shown with a welded steel pontoon. Also, the ends of the bridge varied by builder. Pony plate girder float bridges could be found with tapered ends, rounded ends, square ends:

. . Hybrid Designs: There was one hybrid pontoon type bridge span design. It was composed of plate girders on the outer edges, but with a single tall steel lattice truss down the center. To date, only the Jay Street Terminal in Brooklyn was known to have used this type of composite design, and no clear overall view of the bridge is known. Nor is the construction of the pontoon known. .

steel Through Plate Girder & steel Pony

Truss . |

|

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

.

The Delaware Lackawanna &

Western Railroad Gantlet Track

The Delaware Lackawanna & Western Railroad has been observed to have used a gantlet (also called gauntlet) style of track on its pontoon float bridges located throughout New York Harbor.

While this third set of rails would add nominal weight to the span, it had the benefit of relocating all moving parts of switch points, turnout and switchstand to the float bridge approach on land, which allowed the railroad to employ the use of a standard yard type switch throw, and do away with the condensed "in between track" switch throw so commonly used on other pontoon bridges.

It does not appear that this gantlet track required any modification of the construction design of the float bridge span itself, and all gantlet track construction was contained to the deck top. For viewing purposes, the gantlet track in the diagram below is highlighted in yellow:

.

.

| RETURN TO CHAPTER INDEX | RETURN TO MAIN INDEX |

.

.

Another Misconception: "Pumped Pontoons"

In those other parts of the United States that utilized rail-marine operations, the method to adjust the height of a pontoon type float bridge by pumping water in and out of the pontoon was tried and in some cases found satisfactory.

Unfortunately, many of those not knowledgeable with specific New York Harbor float bridge operations assume what was used in other locations, was used here as well. This is not so and this "pumped pontoon" method did not work well in regards to the operational needs of pontoon float bridge usage in and around New York Harbor (French, 1917, 61).

Several factors put forth for this pumped pontoon method not working in the New York Area of float bridge operation would be:

In winter, water would freeze disabling the pump and / or block pipes (and which would not be an issue on the warmer West Coast where this method was more prevalant);

Debris in the water: seaweed and flotsam in the river would lodge in the pump and pipes causing clogging;

The corrosive effects of salt water on iron pipes and in the iron & steel

pontoons would cause rust and scale to eventually plug up the pipe and corrode

pump seats;

but the most significant factor against "pumped pontoons" in New York Harbor:

The time involved in pumping water into or out of a pontoon. In those cases of float bridge use where freight traffic was not as high volume or hectic as it was in New York Harbor, the few extra minutes it took to pump water in or out of a pontoon was not crucial. In and around New York Harbor however, speed was of the essence and where rail-marine operations swung on the tide, the arrival of perishables for market, express shipments, consigned freight to meet a train and the duty shifts of a tugboat; a tug's crew needed to get its carfloats moored, drilled, and released with as little wasted time as possible.

.

Lifting Gallows.

Therefore, the earliest pontoon float bridges as constructed in New York Harbor utilized overhead lifting gallows. They are often seen in older photographs of pontoon bridges at New York, and these gallows were also used to raise the float bridge for maintenance or replacement of the pontoon.

An important aspect to the operation of float bridges is the method of adjusting the float bridge to match the corresponding height of the carfloat to allow the toggle bars to meet the sockets on the incoming carfloat. Almost always, the float bridge would need to be raised or lowered to meet the deck height of an incoming carfloat. While the pontoon adjusts the bridge height automatically for the tides, it does not do so for variations in height above water of the carfloat itself. This could be due to the size of the carfloat, or the weight of load upon it. It goes without saying empty freight cars are lighter than loaded ones and some loads are lighter than others.

In the initial design of the float bridge, pontoon buoyancy would be calculated and the size of the pontoon allotted for the float bridge to ride higher than the average loaded carfloat. But, there would be those occasions when the float bridge is lower than the oncoming deck of a high riding or "light" carfloat or a slow leak / seepage in a pontoon.

In those cases, the overhead gallows gave a structure in which to raise the float bridge. Most gallows were equipped with one, two or three pulley blocks or chain falls to raise the float bridge as seen in the Brooklyn Navy Yard image below. Another method used was with a hand turned, reduction geared winch mounted on the bridge with the cable fixed to the overhead gantry as seen in the NYNH&H design below.

It must be understood here and now, that the gallows were never used to raise or lower the float bridges during an actual loading of carfloat or carry a live load. (Snow, 1901, 162). Once the float bridge was mated to the carfloat, the cables or chain were slackened.

As construction methods progressed, steel lifting gallows became common place and both plate girder and various truss types were seen. Again, the gallows were only used for lifting or lowering an empty bridge to meet the height of an incoming carfloat, or to service the pontoon under the span. After the bridge was mated "toggled" to the carfloat, the lifting chains slackened and detached.

The overhead gallows could also be used to raise the bridge to service or change the pontoon as needed.

|

|

|

|

.

. It has long been wondered why the overhead gallows fell out of use and in most cases; removed altogether from all but the very few locations around New York Harbor. While not conclusive, it is postulated that as the earliest pontoons were constructed of wood planking, with the seams sealed with pitch and then the pontoon sheathed in copper. As the pitch would dry out, the seam would seep water making the float bridge ride lower and lower in the water. Also, the wood despite treatment would absorb some amount of moisture over time, thereby making it less buoyant. Also, with all the planks having at least two caulked seams (the top and bottom of the plank), it would stand to reason that the seams would need to be recaulked on some sort of basis to prevent leaks.

So, the overhead lifting gallows was a necessity in both regular maintenance and repair to early float bridge design using wood pontoons.

However, just after the turn of the century when iron & steel working was improved and perfected and likewise riveting and welding along with it; steel pontoons became the design choice. Steel pontoons were by design less prone to seepage or leakage, and tolerated being bumped and crashed into by debris or ice better and stood a higher chance of remaining watertight despite that abuse than its wooden pontoon predecessors.

As such, with the proliferation of the metal pontoon, the overhead lifting gallows were no longer needed to assist a leaky or maintenance intensive pontoon and were removed through attrition and replacement / modernization of a float bridge. This might have more merit than we realize, as if one references the images of pontoon float bridges throughout New York Harbor taken by and after the middle of the 20th Century, the original pontoons built in the late 19th Century as well as the float bridges themselves, had reached the end of their expected service life and were replaced. And by proxy the overhead gallows had become an unnecessary fixture, were removed and no longer seen.

Again, this is hypothesis and not conclusive.

|

|

Enter the Hydraulic Float Bridge Jack A later innovation did away with the gallows altogether. A hydraulic jack with a downwards facing extendable piston was mounted to the outboard end (or face) of the float bridge. This apparatus, known as a "float bridge jack" was rigidly mounted to either a steel A shaped frame between the tracks (bearing a remarkable close resemblance to an italic A ) or in the case of wooden Howe truss design, the float bridge jack would be fastened to the end of the center truss. In its position of mounting, the float bridge jack would overhang the end of the float bridge. When a high riding carfloat was positioned under it, and flush up against the bridge, some square wooden blocking (usually cast off sections of railroad ties) would be placed on the deck of the carfloat and under the jack taking up and much space as possible. Then, the jack would be pumped, thereby extending the piston down, taking up the remaining space, when it would contact the blocks and press down on them and likewise against the deck of the carfloat. As the carfloat was more buoyant than the float bridge, the float bridge would "rise" out of the water by the necessary distance, and now allowing the decks of the carfloat and float bridge to be in horizontal alignment. this would in turn allowing the toggles to be inserted into the carfloat toggle receptacles to keep the carfloat & float bridge in lateral and vertical alignment. .

|

|

How Did It Work?

Paul Strubeck noticed there is no handle mounted on the jack cylinder to pump it. That is because there wasn't one. Behind the A-frame on the bridge deck was a small weathertight reservoir (usually a box), containing the hydraulic fluid and with a pump handle.

Most often you can't see this hydraulic fluid reservoir in images because the photographer was standing on the bulkhead or adjacent pier taking pictures and the side girders of the float bridge blocked the view.

Upon special request, John McCluskey took a large array of images of the BEDT Pidgeon Street float bridge (pontoon / pony truss) as well as Paul Strubeck of the float bridge at the Brooklyn Navy Yard (former BEDT North 9th Street float bridge). Both were able to take images showing the hydraulic fluid reservoir and valving, and can be seen in the images above and to right. .

Wood blocking was stacked to take up most of the empty space between the carfloat deck and bottom of the piston.

On one side of this reservoir was a small manually operated pump handle. According to Joe Roborecky, the handle was usually nothing more that a simple bar of steel stock that was flattened on one end to fit in the socket receptacle. The handle receptacle can be seen in the image at upper right. The handle was designed to be removable and taken out of the pump when not needed, and usually left on the bridge. The handle was then pumped which forced hydraulic fluid in the cylinder and thereby extending the piston. Once the space was taken up and the piston rested on top of the wood blocking, the piston began lifting the float bridge to the desired height.

In the images above, the connecting hoses dry rotted long ago, but you can see one of the fittings on the side of the box. The image at right shows one of the hoses dangling. The fittings on the jack cylinder in the image above are in shadow and difficult to discern, and the cylinder is completely gone from the float bridge at BNY. One hose ran from one hand pump to a fitting located near the top of the cylinder and another hose ran from the other pump to a fitting near the bottom of the cylinder.